Introduction

Today, one of the main global challenges is how to ensure food security for a world growing population whilst ensuring long-term sustainable development. The number of food insecure population remains unacceptably high, each year and worldwide, massive quantities of food are lost due to spoilage and infestations on the journey to consumers.1 Based upon a recent study of postharvest losses in both industrialized and developing nations, farmers are estimated to lose over 40% of the value of their produce before it reaches the final consumer because of the produce.3 Drying is the best way to preserve the food. Probably drying was the first continually food preserving method used by mankind even before cooking. It involves removal of moisture from vegetables to preserve it for a longer time.4 Many products are however, must be dried at relatively low temperatures, i.e., less than 100°C to ensure the desired product quality and solar dryers can often be used instead of sun drying or conventional dehydration systems.5 The proposed dryer is well suitable for the low temperature drying for leafy vegetables. Fenugreek and coriander are the group of vegetables popularly used in India and are rich in nutrients.Low-temperature drying allows foods such as green leafy vegetables (e.g.. Fenugreek and coriander) to be dried without losing the original colour and texture.3 The proposed dryer is well suitable for the low temperature drying for leafy vegetables.

Solar cookers and ovens, absorb solar energy and convert it to heat, which is then used for cooking or baking various kinds of food. Standard models with an aperture areas of about 0.25 m2 are the rule for a family of five, and larger versions measuring 1 m2 and more are available for schools, clinics, etc.6 The design of the first solar collector was found in 1767, when Horace de Saussure,a Swiss naturist, invented the self-named “hot box”.7 The uses of different designs of solar cookers have not become acceptable in the rural areas due to number of reasons as per.8 Box-type solar cookers are suitable mainly for the boiling type of cooking. The cooking temperature in this case is close to 100°C. A large fraction of the mass of most food products is due to water. The time for the sensible heating depends on the climatic variables–solar radiation and ambient temperature. To permit evaluation of solar cookers and comparisons between cookers we require cooker parameters that are more or less independent of the climatic variables.9

The solar dryers have been classified on the following criteria.

- Whether or not the drying product is exposed to isolation

- The mode of airflow through dryer

- The temperature of drying airflow circulated to drying chamber.10

In the present study, a multipurpose solar food processor(MCSFP) has been developed both for cooking and drying operation.The performance evaluation (Thermal analysis) of the MCSFP has been carried out in two different modes.

Mode: 1MCSFP as Dryer.

Mode: 2 MCSFP as Cooker

To certify the performance of MCSFP as box-type solar cooker, thermal performance is evaluated in terms of two figures of merit viz. F1 and F2.11 The solar cookers as per12 shall be of two grades depending upon their thermal performance (F1). Grade A – F1 shall not be less than 0.12 Grade B – F1 shall not be less than 0.11.

Mode: 3 MCSFP as both Cooker and Dryer

Materials and Methods

Design Construction of MCSFP

An inclined setup was made in which black coated plenum chamber, annular spaces with two cooking pots were placed in the chamber. Whole setup was covered with insulating glass so that the solar radiation can’t go outside the setup. Behind the setup, the drying chamber was made which uses the hot air coming from the annular spaces. In dryer, an outlet was provided for the moisture to leave from the crop/vegetables to be dried. Also, the dryer was insulated with the aluminum foil as a thermal insulation.

Table 1: The experimental set-up of solar food processor was constructed with following specifications.

| Materials | Quantity | Size |

| Drying chamber | 1 | 400mm X 280mm X 210mm |

| Cooking chamber | 1 | 615mm X 355mmX 100mm |

| Annular space | 1465 cm2 | |

| P.V.C pipes | 3 | 25.4mm dia., 153mm in length |

| G.I sheet | 1 | 38.1mm X 66.0mm (24SWG) |

| Wood strips | 35 feet in length | |

| Plywood | 2 | 183mm X 915cm X 6mm |

| Glass plate | 863mm X 500mm | |

| Ball valve | 2 | 25.4mm dia. |

| Thermo-col | 4 | 430 mm X 1220mm X 6mm |

| Thermo-col Box | 1 | 440mm X 350mm X 25mm |

Air Circulation System

Valves provided at the front-end acts as inlets and accept the air at ambient temperature and allow the same in to drying chamber through annular spaces. The cooking chamber and air in the annular spaces get heated with the radiation arrested under the insulating glass and is used for cooking and drying functions. Heated air entering the drying chamber passes through the food material to be dried and leaves the chamber through the outlets provided at the rear end.

Fenugreek

Fenugreek leaves were obtained from local vegetable market. Collection of homogeneous fenugreek leaves were obtained by removing the non-leafy parts. A 100 grams sample is being collected and washed to remove any dust present in it and placed in the tray of drying chamber.

Experimental Procedure

Tests were performed from November through December 2016 at College of Agricultural Engineering & Technology, Godhra,Gujarat, India. During the tests, the ambient temperature, tray temperature in drying chamber, cooking chamber and solar radiations were measured using Gema make mercury Thermometer and Pyranometer respectively at regular intervals of time. Air flow rate and weight loss of drying material measured by anemometer of Prova Instruments Inc., Kern make Digital Weighing Balance of sensitivity 0.1grams.

MCSFP as Dryer: Mode 1-(M1)

Developed cooker was initially used only as a dryer.Three iterations were carried out. Each iteration took one complete sunny day to get sample with an acceptable level of moisture content.

During the tests, the ambient temperature, tray temperature in drying chamber and solar radiations were measured All the readings were recorded at 1 Hr. interval from 09:00 Hrs. to 17:00 Hrs. At every hour, drying material was removed from the drying chamber for about 40 to 50 seconds for weighing the product for moisture content calculation.

Thermal Analysis

Thermal analysis enables to understand how well a dryer operates under a specific condition.

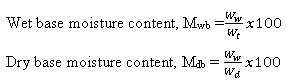

Solar radiation, temperature inside the drying chamber, airflow rate, moisture contents were used for thermal analysis and moisture contents were calculated as follows

Where Ww = weight of water in the material in gm

Wt = total weight of the material in gm

Wd= total weight of the dried matter of the product in gm

MCSFP as Cooker: Mode 2- (M2)

Secondly, MCSFP was used only as a cooker. During this mode of operation, thermal performance test was carried out to evaluate its performance as a solar cooker. Figure of merits F1 & F2 were calculated using Stagnation temperature test and Sensible Heating of water respectively.

Stagnation temperature test

The cooker was placed in the open sun condition without pot in it. Temperatures of cooker tray were measured continuously at an interval of 5 minutes. Ambient temperatures, solar radiations and airflow rates too were measured. When the cooker tray temperature reached the quasi steady state, the steady cooker tray temperature(Tpz), its corresponding ambient(Taz) and solar radiation (Gs) were noted down. With the recordings, the First Figure of Merit,F1 was calculated as

Sensible Heating of Water Test

Empty pots were weighed and later filled with 1 litre of water. The temperature of the water was then at ambient temperature. The pot was placed in the cooking chamber. Thermometer tip for measuring the temperature of the water was submerged in water. The area where hot air leaving thermometer was sealed completely to avoid any leakages.

The test started at 9:00 Hrs in the morning. The temperature of solar cooker and radiations were measured every 10 minutes continuously till 17:00 Hrs in the evening. Water temperature was recorded with its exact time. Also, solar radiation was recorded in parallel. Time taken to reach the water to raise its temperature from ambient to boiling or near to boiling was observed.

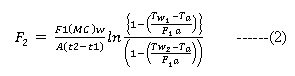

With the data recorded, the second figure of merit F2 was calculated as,

Where

F1= First figure of merit from stagnation test

(MC)w = Mass of water and specific heat in J/

A= Aperture area of the cooker of cover plate in m2

(t2 – t1) = Time taken to heat from Tw1 to Tw2 in seconds

Tα = average air temperature over time period (t2 – t1) in °C and

G = Average radiation over time period ((t2 – t1) in W/m2

After the calculation of figure of merits, Tuvar dal of 200 gms and Rice of 250 gms were cooked in the cooker and the time taken to cook were recorded.

MCSFP as Dryer and Cooker : Mode 3 – (M3)

In the third mode of operation, the MCSFP was used both dryer and cooker. A sample of 100 gms of Fenugreek leaves were collected and placed in tray of the drying chamber. Also at the same time Rice of 250 gms and Tuvar Dal of 200gms were placed in the cooking chamber. The measurements were made accordingly.

Results and Discussion

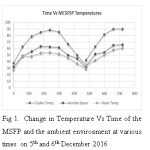

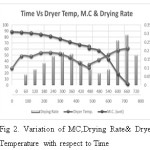

In case of Mode 1-(M1) the temperatures in the drying chamber ranged between 28°C and 61°C. The minimum temperature in drying chamber was observed as 28°C at 9:15Hrs and maximum temperature as 61°C at 13:15Hrs while the ambient temperatures at the said times were 25°C and 34°C respectively. The best suitable temperatures for the drying of fenugreek leaves was 45°C to 60°C which can be attained by the MCSFP drying chamber in between 10:15 Hrs and 13:15 Hrs. The trial data collected on 05th and 06th December 2016.

The time period between the temperatures 45°C to 60°C was considered critical for drying of fenugreek leaves. The safe storage moisture content (Wb) of the fenugreek sample was reduced from 88.4% to 1.29% through 11 hours during trial period.

|

Figure 1: Multipurpose Mixed Mode Cabinet Solar Food Processor Click here to View figure |

|

Figure 2: Variation of MC,Drying Rate& Dryer Temperature with respect to Time Click here to View figure |

The temperature variations with respect to time at different conditions ambient temperature, cooker temperature, drying chamber, moisture content and drying rate variations are shown in Fig 1 & 2. The trend shows that with the decrease in moisture content resulted in increased drying rate.

During Mode 2-(M2)Figure of merits F1 and F2 were calculated using Stagnation and Sensible Heating Tests.

|

Figure 3: Time Vs Cooker, Ambient and Solar Radiations during Stagnation Test conducted on 3rd December 2016 Click here to View figure |

Figure 3 shows the variations of solar cooker temperature and ambient temperatures along with variations in the solar radiation between local solar times13:20Hrs and 14:00 Hrs. The test was conducted between 9:25 Hrs and 15:35Hrs. Readings were recorded for every 5 minutes.

First Figure of Merit (F1)

The steady state conditions were observed for a defined period of 10 minutes when the variation in cooker temperature was 0.5°C, variation in solar radiation is ±14W/and variation in ambient temperature is 0°C.

The cooker attained quasi steady state between 13:35 Hrs and 13:45 Hrs. During the quasi steady state, the cooker temperature(Tpz) and ambient temperature (Taz )was observed as 84°C and 33 °C respectively. The average solar radiation during the quasi steady state was 462 W/.

With the data collected, the First of figure of merit through Stagnation test was calculated as 0.11.

F1 ranges from 0.11 to 0.12 for commercial solar cookers and the MCSFP got the value of F1 well falls under the category of commercial solar cookers. It is also greater than the F1 (0.09) of card board made solar cooker made by Adewole et.al.(2015)

Second Figure of Merit (F2)

Variations of Ambient, Cooker and Water temperatures with respect to Solar Radiations during Sensible Heating Tests conducted for 1.0Kg(1.0 Litres) of water on 19th December 2016 were shown in figure 4. The tests were conducted between times 09:30 Hrs and 16:00 Hrs. The solar radiations fluctuations were recorded during the test. The maximum and minimum insolations were noted as 562 w/m2 and 222 w/m2 at 12:30 Hrs and 16:00Hrs. 392w/m2 and 38°C were the average values of solar radiation and ambient temperatures respectively.74°C was the highest water temperature reached in cooker at 13:50 Hrs. Water temperature is significantly raised up to 15:00 Hrs which shows the heat transfer between the absorber plate and cooking vessel is good with less thermal losses.

|

Figure 4: Variation of Ambient, Cooker and Water temperatures with respect to Solar Radiations during Sensible Heating Tests conducted on 19th December 2016 Click here to View figure |

Second figure of merit of developed cooker (F2) is calculated using equation (2).

Varying temperatures in the cooker were shown in cooker figure (4). To raise the temperature from 65°C(Tw1) to 75°C(Tw2) of 1Kg of water, the time required was about 70 minutes. Values of Tw1 and Tw2were chosen with some flexibility i.e., Tw1>Ta was recommended in[ 8] and Tw2 was recommended to be a lesser value than the boiling point of the water. As per Bureau of Indian Standards, the second figure of merit (F2) should not be less than 0.40. The F2 value obtained using equation (2) during the test was 0.41 which is meeting Indian standard specifications.

MCSFP application for cooking Rice

200 Grams of rice was collected in a vessel and placed in the cooking chamber at 10:00 Hrs on 22nd November 2016. Figure 5 shows the variation of solar radiation and temperature of ambient and cooker with respect to time.

|

Figure 5: Variation of Solar radiation and Cooker Temperature with respect to time Click here to View figure |

It was observed that the minimum and maximum solar radiations recorded during the cooking time was 396 w/m2 at 10:00 Hrs and 548 w/m2 at 13:00 Hrs. While the cooking chamber temperatures were recorded as 72°C minimum at 10:00 Hrs and 90°C at 12:00Hrs. It took two hours for the rice shown in figure 6 to cook.

|

Figure 6: Rice cooked in the cooking chamber of MCSFP Click here to View figure |

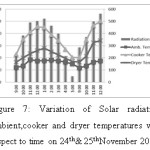

In operation of Mode 3 – (M3), both cooker and dryer were made functional simultaneously.A sample of 250 gms of rice was placed in the cooking chamber at 10:00 Hrs. and a sample of 100 gms of fenugreek leaves were collected and placed in a tray of the drying chamber at 11:00 Hrs. on 24thNovember 2016. The measurements were made accordingly.Figure 7 shows temperature profile variations and solar radiation changes with respect to time. The maximum temperature observed in the cooking chamber on load was 91°C at 13:00Hrs.Rice cooked in two hours and is shown in figure 9(a).

|

Figure 7: Variation of Solar radiation, ambient,cooker and dryer temperatures with respect to time on 24th& 25thNovember 2016 Click here to View figure |

|

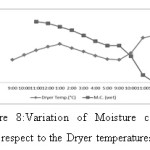

Figure 8: Variation of Moisture content with respect to the Dryer temperatures Click here to View figure |

Moisture content(wet basis) variation and drying rates with respect to the times were shown in figure 8. Total drying was carried out for 9 Hours. The temperatures in the drying chamber was varied bewteen 35°C to 69°C. The temperatures recorded were best suited for the drying of fenugreek leaves. Moisture content was reduced from 88.5% to 3%. Figure 9(b&c) shows fenugreek leaves before and after drying respectively.

|

Figure 9: Rice cooked in 2 Hrs on 24th November 2016 and Dried fenugreek leaves after 9 Hrs of drying on 24th and 25th November 2016 Click here to View figure |

Conclusion

In the present work, a multi-purpose mixed mode cabinet solar food processor developed and tested for its thermal performance. The tests carried out in three different modes of operation. Mode 1: when MCSFP used only as Dryer. The minimum temperature in drying chamber was observed as 28°C at 9:15 Hrs and maximum temperature as 61°C at 13:15Hrs. These temperatures are best suitable for leafy vegetables.

In mode 2, the MCSFP was used only as solar cooker. The water temperature values during the sensible heat testing were 650C and 750C. First and Second figure of merits calculated as 0.11 and 0.41 respectively were favourable in terms of the Bureau of Indian standards. The cooking of rice was done in two hours.

In mode 3, the MCSFP was used both as cooker and dryer with samples of 250 grams rice for cooking and 100gms of fenugreek for drying placed in it. Cooking was done in 2 hours and the drying carried out for 9 hours.

The experimental results obtained from the prototype of MCSFP were found better for performing cooking and drying simultaneously and best results can be obtained with final development of MCSFP having no leakages. It is observed from the experimental results, the MCSFP was operating well even for the varying weather conditions.

Acknowledgements

Authors are grateful to Anand Agricultural University for support in doing the presented work.

References

- Victor K., Post Harvest Losses and Strategies to Reduce Them. ACF International. 2014

- James S., Simon L., Pieter S., Jim T., Bertha M., Kurt K., Diane M. B., Performance evaluation of an enhanced fruit solar dryer using concentrating panels. Energy Sustain Dev. 2012;16:224–230.

- Arun K.A., Nitin K., Yogender K.Y., Performance Evaluation of a Dehumidifier Assisted Low Temperature Based Food Drying System. IOSR J Env Sci, Toxicol Food Techno. 2014;8:43-49.

- Navale S.R., Harpale V.M., Mohite K.C., Drying of Fenugreek leaves by cabinet solar dryer and open sun. Int. J Renew. energy environ. eng. 2015;3

- Fuller R.J. Solar drying-a technology for sustainable agriculture and food production. Sol Energy Convers Photoenergy Syst. 2000;3:25.

- Kuhnke, K., Reuber, M., & Schwefel, D., Solar Cookers in the third world. Vieweg & Sohn, Braunschweig/Wiesbagen. 1990.

- Real L., Sierra E., Almena A., Renewable Energy Sector. In: Martín M. (eds) Alternative Energy Sources and Technologies. Springer. 2016.

CrossRef - Adewole, B.Z., Popoola, O.T. and Asere, A.A., Thermal Performance of a Reflector Based Solar Box Cooker Implemented in Ile-Ife, Nigeria. Int. J of Energy Eng. 2015;5:95-101

- Mullick, S.C., Kandpal, T.C. and Saxena, A.K., Thermal test procedure for box-type solar cookers. Sol Energy. 1987;39(4):353-360.

CrossRef - Sayyad, Farid & Sardar, Nilesh & Rathod, Jaydipsinh & A Baria, U & Yaduvanshi, Birjesh & P Solanki, B & J Chavda, J., Design and Development of Solar Cooker cum Dryer. Current World Environment. 2015;10:985-993.

CrossRef - Purohit, I. and Purohit, P.,. Instrumentation error analysis of a box-type solar cooker. Energy Convers. Manag. 2009;50:365-375.

CrossRef - IS13429-1, Solar Cooker – Box-type, Part 1: Requirements, Med 4: Non-Conventional Energy Sources, Bureau of India Standards. 2000.