Introduction

China, United States and Brazil are the leading maize producing countries globally with an estimated production of 563 metric tons/year 1. Maize is the most important food security crop in Kenya and plays a huge role in human nutrition with an estimated consumption of between 171g/person/day to 233g/person/day where it is estimated that about 25% of the total harvest is lost due to aflatoxin contamination 2 .The government of Kenya has been on a look out to the maize and maize products manufacturers on the issue of initiatives implementation to decrease the level of aflatoxin of the end products that is accessed in the markets. In Kenya, maize grains are a staple food consumed by members in the households and it’s highly consumed by small -scale members 3. They are consumed locally as flour, whole grain and muthokoi, as composite flour for porridge preparation and as a component of the animal feeds. It’s used in the manufacturing of oil .Ready-to-Use Therapeutic Food (RUTF) has maize flour as the main ingredient for malnourished children feeding 4. They have a risk of aflatoxin exposure to consumers when consumed when not properly sorted from moldy, shriveled, and damaged from insect and the kernels that are broken 5. Aflatoxin is toxigenic, carcinogenic and mutagenic microorganism which lead to adverse health complications across the age groups who consumes the cereal based products. It’s produced by Aspergillus parasiticus and Aspergillus flavus, found in humid and warm environment mostly affecting cereals which include nuts and maize grains. Maize, being the main staple food in Kenya and other countries in sub-Saharan African, its consumption is high and regular posing the risk of exposure to aflatoxins. Contamination can occur in the field during harvesting process and under storage facilities. However, post- harvest contamination is highly facilitated by the climate present during the harvesting time 6. Drying on a bare soil lead to contamination after the harvesting process to the maize grains 7. An incidence of 8% to 21% of maize in aflatoxin in Kenya was reported to be above the recommended the Food and Drug Administration (FDA) limits of 20 parts per billion8. Increased aflatoxin contamination was reported subsequently in food products and grains that were available in households and markets 9. Health consequences and adverse nutrition effects were found after contaminated food were consumed 10. Long-term aflatoxin exposure led to chronic health impacts which include cancer and stunting effects and acute exposure bring the aflatoxicosis or death effects 11.

Trade can be negatively impacted upon grain contamination 12. Maize millers can reduce aflatoxin contamination in the maize grains before milling and packaging by adopting appropriate practices such as timely use of chemical, physical and biological methods of decontamination 13. Maize grains handlers in the milling plant’ mitigations of contamination are achieved through proper sorting, elimination of shriveled and damaged kernels, aerated storage facilities, and also the use of hermetic bags 14. Food safety management in a maize milling set up is well monitored by Hazard Analysis Critical Control Point (HACCP) principles incorporation which are guided by the maize millers’ positive knowledge, appropriate attitude and practices (KAP) on aflatoxin contamination control. There is need for several training programs to maize handlers from the farm to the industries due to the reported aflatoxin contamination severity in Kenya 15. The attitude in practicing aflatoxin mitigation approaches and the implementation is less studied in Kenya hence maize handlers KAP on aflatoxin is less practiced 16. Hence, there is need to assess the KAP of the maize millers so as to sensitize the millers, handlers and the consumers of the products on the level of integrity that is put on so as to ensure that there is safety in consuming maize and its products.

Methods

Study site

Kiambu county has a land area of 2,417,735 square kilometers and borders Nairobi and Kajiado counties to the south, Machakos to the East, Murang’a to the North and North East, Nyandarua to the North West and Nakuru to the West as shown in figure 1. The county has a population of 1, 782,083 17. The county has an average annual rainfall of 1,200 mm and a mean temperature of 26 0C. According to the 2019 census, there is a total population of 2,417,735 in the county: 1,187,146 males, 1,230,454 females, and 135 intersex persons with 796,241 households and the average household size of 3.0 persons per household and a population density of 952 people/km2 18.

|

Figure 1: Map of Kenya showing the location of Kiambu County. Key: Red: Location of Kiambu County |

Source: 19

Determination of sample size

Kiambu County has 42 millers as per the Kenya Bureau of Standards to year 2022 which are distributed among the 12 sub-counties. The Yamane method,20was used with a 95% confidence interval and error level of 0.1 to calculate the minimum number of millers which were supposed to be used in the study.

nYamane = N / (1 + Ne2) where n was the number of sample size, N the size of the population and e, the allowed error.

Where nYamane=42/ (1+42(0.1)2)

=30 maize millers

Study design

The study design used was cross sectional. Assessment of the handling knowledge, attitude and practices on HACCP was done to the maize miller’s management, raw material, milling, packaging and the dispatch sections to meet the standards of Food Safety Management System from ISO 22000:2018. The sampling of the individuals from the milling sub- sections was done through random method of sampling where they were interviewed from each sub- section.

Sampling procedure

The clustering method was used to sample the millers depending on the ranking factors which included; Industry size, daily production and annual production then picked them using the systematic sampling method. The study population was the maize millers from Kiambu County. Data was collected by the use of the semi- structured questionnaire across all the sub- sections randomly from the sampled millers. The questionnaires containing the general questions on knowledge, attitude and practices (KAP) and the social demographic characteristics were administered to the 150 respondents who were selected randomly from the milling sub- sections. There were some sub- counties that didn’t have the maize milling plants and therefore they were not included in the study.

Study tools

A semi- structured questionnaire was developed eliciting qualitative information mostly with open –ended questions. It was first tested through presenting it to a group of food safety researchers for the verification of its validity and reliability. Face-to-face interview was used to administer the questions with a selected individual from each sub- section of the milling set up. Different questions from the questionnaires were summarized using checklist that ensured the answers given were correct. Unique answers and different types of replies were determined. It was measured by categorizing the 14 items as knowledgeable or not knowledgeable. Attitude on HACCP by the handlers was also accessed where the thoughts and the behaviors towards the system on reducing the aflatoxin in maize was determined all the answers towards the aflatoxin attitude were measured by use of 12 questions. Five Likert’s scale was used giving the scores and the degree of agreement or disagreement which include; Strongly disagree, Disagree, Neutral, Agree, strongly agree. The behaviors of the maize products handlers in the aim of reducing the aflatoxin content were accessed in terms of practices that are put into place which incorporates the HACCP system.

Quality control

The questionnaire was first tested through presenting it to a group of food safety researchers for the verification of its validity and reliability. To ensure that the data collected was accurate, the interviewers were well informed on the key information they needed to collect data on and also the interviewees were well sensitized on the specific data that they were needed to give. If an interviewee gave incomplete data, they were required to interpret further so as to capture the right information even if it meant them to consult the supervisors in charge in the specific section of the milling system. The questionnaire was thoroughly proof led to ensure that it captured the only required information as per the objective and also to eliminate the duplication of the questions to enhance the data uniqueness. The already filled questionnaires were sealed completely to avoid the chances of misplacement or changing of the already given data.

Ethical considerations

The respondents who were interviewed were sampled on voluntary bases, signed the consent form to show the acceptance to participate in the survey. The data provided by the millers were subjected to a high level of confidentiality and privacy. Only the data relevant to this study were collected from the millers. Since the maize millers’ products’ safety is monitored and regulated by the standard body, KEBS offered an authority letter as an access to the milling facilities.

Study hypothesis

Kiambu county maize millers’ socioeconomic variables were not significant linear predictors of HACCP knowledge, attitude and practices towards aflatoxin contamination in the maize and the products.

Data analysis

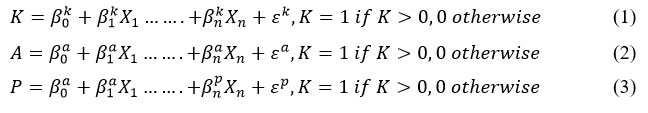

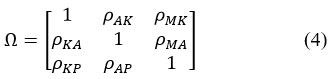

This study adopted the use of a multivariate probit (MVP) and the multinomial logistic regression (MNL) models as the analytical framework for evaluating the food safety handling knowledge, attitude, and practices of maize and maize products millers. In this case, the MVP accounted for correlation as it modeled the effect of a set of covariates on the KAP responses while taking care of the correlated unobserved error terms. MVP was flexible to accommodate for the potential correlation of responses elicited from the knowledge, attitude, and practices on maize food safety handling. It’s an extension of the bivariate probit which utilizes the Monte Carlo simulation techniques to jointly estimate the multiple probit equation systems 21.

The MVP is explained in terms in the form of a correlated multivariate normal distribution that considers the underlying latent variables which are expressed as discrete variables through a threshold specification, and thus allows the flexible modeling of the correlation structure and the simple interpretation of the observed parameters. Given that Knowledge (K), Attitude (A), and Practices (P) are a binary function of the decision makers and maize millers’ characteristics, the MVP model is thus specified as below:

Where β is the vector parameters to be estimated, X is a vector of miller’s characteristics, and ε is a vector of the error term. The error terms should thus follow a multivariate normal (MNV) distribution that depicts a zero conditional mean, with a variance normalized to unity 22, ε~MNV(0, Ω), where Ω is the systemic covariance matrix which is defined as follows:

Where 𝜌 is the unobserved correlation of the KAP equations. In the case that 𝜌 was significant, it implied the interdependence between the error terms. A positive value of 𝜌 was considered as promotive between the measured pair of equations, whereas, a negative value of 𝜌 was substitutive. The variables that had an effect on the dependent variables (KAP), the three MVP regression equation analysis was fitted with a similar set of independent variables across the equations. These included socioeconomic and social demographic aspects such as duration of employment, age, year of education, gender and marital status, food science experts, were the hypothesized variables that influenced the knowledge, attitude, and practices on HACCP.

The research instrument was pre-tested to identify any problem with the content of the questionnaire including confusion with the overall meaning of the questions or misinterpretation of any term. This was done through administering to one maize milling company and based on the outcome of the pre-testing, modifications were made to the questionnaire.

Results

Socio- demographic characteristics of maize handlers in the milling firms

Overall, 150 respondents from milling firms in Kiambu County participated in the study. Majority 60% of the respondents were male with the raw material handling having the highest representation of males at 86.7% while the management section comprised of 63% males. The latter finding implies that at least one third of the management of the milling firms consisted of females. Most of the respondents (44.7%) had only completed secondary education while 34% had attended college or university. The management section had the highest number with college or university education (80%) while the dispatch section had the most respondents with primary school only level of education. The mean age of the respondents was 39.81 ± 8.784 years; the management section had the highest mean age at 42.93 ± 8.457 years while the dispatch section had the lowest mean age at 38.03 ± 8.331 years. Further, majority (78.7%) of the respondents were married with at least 70% of the respondents in every section indicating that they were married. Most of the respondents were employed on a part time basis (58%). Majority (76.7%) of the respondents who were employed full time were in the management section while the raw material handling and packaging sections had the lowest proportion of full-time employees each at 30%. Most of the respondents had worked in the milling firms for between 5 and 10 years (30.7%). The section with the most experienced workers was the packaging section where 33.3% of the respondent reported that they had worked for between 21 and 30 years. However, the management and milling section had the lowest number of respondents who had over 20 years’ experience (6.7%). Finally, in terms of food security training, majority (84.7%) of the respondents indicated that they had received the FS training.

Knowledge of the respondents

The average HACCP knowledge for the millers in Kiambu County was 57.5 ± 31.526%. HACCP knowledge was highest among the management section and lowest at the dispatch section as shown in the table 1. The binomial logistic regression model was statistically significant at p < .001, χ2 (8) = 26.475. The model explained 47.6% (Nagelkerke R2) of the variance in HACCP knowledge and correctly classified 93.3% of the cases.

|

Table 1: Maize products handlers’ Knowledge on HACCP in mitigating Aflatoxin (N= 150) |

Table 2, shows the linear model of the socio-economic predictor factors of HACCP knowledge on aflatoxin reduction in the maize flour milling chain from the millers in Kiambu County.

Table 2: Linear model of socio-economic predictor factors of HACCP knowledge scores of millers (N=150)

| Categorical Variable | B | S.E. | Wald | P-value | Odds Ratios |

| Constant | 4.316 | 2.234 | 3.731 | 0.053 | 74.855 |

| Gender | -0.098 | 0.602 | 0.027 | 0.871 | 0.907 |

| Education level | 0.972 | 0.476 | 4.168 | 0.041 | 2.643 |

| Age in Years | -0.014 | 0.032 | 0.199 | 0.656 | 0.986 |

| Marital status | -0.137 | 0.295 | 0.216 | 0.642 | 0.872 |

| Employment status | 1.247 | 0.673 | 3.431 | 0.064 | 3.48 |

| Length of Service | -1.701 | 0.441 | 14.869 | 0.000 | 0.183 |

| Work Section | -0.107 | 0.219 | 0.24 | 0.624 | 0.898 |

Adjusted R2 = .476, p ≤ 0.05

Attitude assessment

The aggregate mean score for HACCP attitude among the millers was 3.326 as per the Likert scale and a standard deviation of 1.0894 as shown in table 3. Multinomial logistic regression was used to assess the HACCP attitude along the socioeconomic and food safety training variables among the millers. The regression model significantly fit all the variables at p < .001 and explained 68.7% (Nagelkerke R2) of the variance in HACCP attitudes.

Table 3: Maize products handlers’ attitude on HACCP towards aflatoxin mitigation

| General HACCP attitude | Management | Raw material section | Milling section | Packaging section | Dispatch section | |||||

| Mean | Mean | Mean | Mean | Mean | ||||||

| The principle of HACCP system is to prevent aflatoxins in the stages before the endpoint of production | 4.17 | ±0.592 | 3.7 | ±0.75 | 3.67 | ±0.758 | 3.9 | ±0.96 | 3.9 | ±1.348 |

| According to prerequisite programs it is enough to clean the milling system only before starting | 3.5 | ±0.974 | 3.07 | ±0.868 | 3.2 | ±1.297 | 3.23 | ±1.251 | 3.57 | ±1.104 |

| HACCP is an obligatory system that all food related plants should apply | 3.13 | ±0.973 | 3.5 | ±0.82 | 3.4 | ±1.163 | 3.03 | ±1.033 | 2.9 | ±0.995 |

| HACCP is not a very effective system to provide food safety | 3.5 | ±0.777 | 3.13 | ±0.973 | 2.83 | ±1.234 | 3.23 | ±1.104 | 2.87 | ±1.042 |

| HACCP is a mandatory system in Kenyan food law | 3.4 | ±0.77 | 3.07 | ±1.112 | 3.07 | ±1.048 | 3.33 | ±1.213 | 2.97 | ±1.098 |

| Each hazard that may reflect to end product should be identified and recorded according to HACCP principles | 3.53 | ±0.776 | 3.4 | ±0.968 | 3.1 | ±1.094 | 3.53 | ±1.57 | 3.2 | ±1.648 |

| HACCP is a food safety law specific to our country | 3.53 | ±0.776 | 3.2 | ±0.997 | 2.8 | ±1.095 | 3.1 | ±1.296 | 3.07 | ±1.507 |

| Prerequisite programs that include all hygiene rules must be fulfilled prior to the implementation of the HACCP system | 3.73 | ±0.828 | 3.07 | ±1.048 | 3.03 | ±1.033 | 3.63 | ±1.45 | 3.27 | ±1.552 |

| The HACCP system requires staff training in hygiene | 3.53 | ±0.9 | 3.63 | ±0.964 | 3.37 | ±1.098 | 3.63 | ±1.066 | 2.37 | ±1.033 |

| Prerequisite programs are accepted as infrastructure of any food business | 3.6 | ±0.724 | 3.47 | ±1.042 | 2.9 | ±1.125 | 3.17 | ±1.44 | 3.23 | ±1.547 |

| Microbiological hazards cannot be included in HACCP | 3.6 | ±0.621 | 3.3 | ±1.208 | 3.27 | ±1.437 | 3.23 | ±1.165 | 3.1 | ±1.094 |

| It is essential to keep track of and to record every step of food production in HACCP system | 4.37 | ±0.718 | 3.77 | ±1.431 | 3.23 | ±1.135 | 3.3 | ±1.343 | 3.03 | ±1.377 |

| Aggregate | 3.633 | ±0.786 | 3.359 | ±1.015 | 3.156 | ±1.126 | 3.359 | ±1.241 | 3.123 | ±1.279 |

The regression model was significant at P< .001

Table 4, shows the linear model of socio- economic predictor factors of HACCP attitude scores towards aflatoxin reduction in maize flour from millers in Kiambu County.

Table 4: Linear model of socioeconomic predictor factors of HACCP attitude scores of millers (N=150)

| Categorical Variable | B | S.E. | Wald | P-value | Odds Ratios |

| Constant | -1.038 | 3.773 | 0.076 | 0.783 | |

| Gender | 1.525 | 1.555 | 0.962 | 0.327 | 4.597 |

| Education level | 0.133 | 1.809 | 0.005 | 0.942 | 1.142 |

| Age in Years | 0.093 | 0.089 | 1.085 | 0.298 | 1.097 |

| Marital status | 1.196 | 2.679 | 0.199 | 0.655 | 3.305 |

| Employment status | -2.706 | 1.685 | 2.581 | 0.108 | 0.067 |

| Length of Service [˂5 years] | 16.38 | 1.221 | 179.928 | 0.000 | 357.48 |

| Work Section [milling section] | 19.301 | 1.754 | 121.116 | 0.000 | 702.7 |

| Food Safety Training [No] | -3.292 | 1.620 | 4.129 | 0.042 | 0.037 |

Assessment of Practices of Aflatoxin Accumulation

The study also examined the practices related to aflatoxin accumulations across the various sections in the milling firms. The findings are summarized in Table 5.

Table 5: Practices of Aflatoxin Accumulation

| Section | Practices related to Aflatoxin Accumulations | ||||

| Yes | % | No | % | ||

| Management | Employment of food safety and related field experts | 17 | 57% | 13 | 43% |

| Training the employees on Food safety frequently | 9 | 30% | 21 | 70% | |

| Incorporation of HACCP in maize flour production | 5 | 17% | 25 | 83% | |

| Buying of moisture and Aflatoxin testing machines | 11 | 37% | 19 | 63% | |

| Ensuring a track record of maize flour batches sold out | 10 | 33% | 20 | 67% | |

| Fully installation of prerequisite programs in the firm | 7 | 23% | 23 | 77% | |

| Sub -contracting analysis of aflatoxin | 7 | 23% | 23 | 77% | |

| Aggregate | 31.4% | 68.6% | |||

| Raw material | Analysis of aflatoxin | 17 | 57% | 13 | 43% |

| section | Analysis of moisture content | 20 | 67% | 10 | 33% |

| Drying on a mat | 17 | 57% | 13 | 43% | |

| Manual sorting | 24 | 80% | 6 | 20% | |

| Electric sorting | 3 | 10% | 27 | 90% | |

| UV sorting | 3 | 10% | 27 | 90% | |

| Sun drying | 23 | 77% | 7 | 23% | |

| Electric drying | 7 | 23% | 23 | 77% | |

| Sisal Bags | 20 | 67% | 10 | 33% | |

| Airtight Bins | 10 | 33% | 20 | 67% | |

| Hermetic Bins | 30 | 100% | 0 | 0% | |

| Insecticides | 14 | 47% | 16 | 53% | |

| None | 15 | 50% | 15 | 50% | |

| Aggregate | 52.1% | 47.9% | |||

| Milling section | Verification of cleaning of the maize grains | 9 | 30% | 21 | 70% |

| Verification of cleanliness of the milling system | 6 | 20% | 24 | 80% | |

| Cross contamination assessment | 5 | 17% | 25 | 83% | |

| Aggregate | 22.2% | 77.8% | |||

| Packaging | Automated packaging | 4 | 13% | 26 | 87% |

| section | Use of stainless-steel scoping materials | 20 | 67% | 10 | 33% |

| Use of stainless- steel storage bin | 26 | 87% | 4 | 13% | |

| Use of a different room for packaging | 7 | 23% | 23 | 77% | |

| Storage of the packaged flour in a cool dry place | 12 | 40% | 18 | 60% | |

| Storage on ranks | 15 | 50% | 15 | 50% | |

| Stored in aerated rooms | 12 | 40% | 18 | 60% | |

| Aggregate | 45.7% | 54.3% | |||

| Dispatch | Keeping records of the dispatched batches | 18 | 60% | 12 | 40% |

| section | Use of no hooks during loading | 27 | 90% | 3 | 10% |

| Closing of the loaded trucks to avoid rains penetration | 27 | 90% | 3 | 10% | |

| Aggregate | 80.0% | 20.0% | |||

Relationships between HACCP knowledge, attitudes and aflatoxin accumulations control

Following these findings, there was also need to establish whether HACCP knowledge and attitudes on HACCP system on food safety significantly contributed to the practices related to aflatoxin accumulations control where multiple regressions were carried out HACCP knowledge and HACCP attitudes as the independent variables, the aflatoxin accumulations control practices as the dependent variable where p ≤ 0.05. The findings are summarized in Table 6.

Table 6: HACCP Knowledge and Attitudes on Practices of Aflatoxin Accumulation

| Section | Practice | HACCP knowledge | HACCP Attitude | ||

| Chi-Square | Chi-Square | ||||

| Value | P-value | Value | P-value | ||

| Management | Employment of food safety and related field experts | 4.588 | 0.032 | 5.635 | 0.228 |

| Training the employees on Food safety frequently | 2.571 | 0.109 | 3.593 | 0.464 | |

| Incorporation of HACCP in maize flour production | 30.000 | 0.000 | 5.905 | 0.206 | |

| Buying of moisture and Aflatoxin testing machines | 10.364 | 0.001 | 4.456 | 0.348 | |

| Ensuring a track record of maize flour batches sold out | 3.000 | 0.083 | 3.077 | 0.545 | |

| Fully installation of prerequisite programs in the firm | 19.714 | 0.000 | 4.082 | 0.395 | |

| Sub -contracting analysis of aflatoxin | 1.826 | 0.177 | 1.033 | 0.905 | |

| Raw | Analysis of aflatoxin | .084 | 0.773 | 6.656 | 0.155 |

| material | Analysis of moisture content | .577 | 0.448 | 7.259 | 0.123 |

| section | Drying on a mat | .084 | 0.773 | 6.656 | 0.155 |

| Manual sorting | .072 | 0.788 | 5.223 | 0.265 | |

| Electric sorting | .513 | 0.474 | 2.619 | 0.623 | |

| Uv sorting | .513 | 0.474 | 7.778 | 0.100 | |

| Sun drying | 1.405 | 0.236 | 7.839 | 0.098 | |

| Electric drying | 1.405 | 0.236 | 7.839 | 0.098 | |

| Sisal Bags | 2.308 | 0.129 | 5.330 | 0.255 | |

| Airtight Bins | 2.308 | 0.129 | 5.330 | 0.255 | |

| Hermetic Bins | – | – | – | – | |

| Insecticides | 5.275 | 0.022 | 3.023 | 0.554 | |

| None | 4.615 | 0.032 | 2.286 | 0.683 | |

| Milling | Verification of cleaning of the maize grains | 2.571 | 0.109 | 16.813 | 0.001 |

| section | Verification of cleanliness of the milling system | 13.500 | 0.000 | 15.302 | 0.002 |

| Cross contamination assessment | 1.200 | 0.273 | 4.062 | 0.255 | |

| Packaging | Automated packaging | 5.370 | 0.020 | 30.000 | 0.000 |

| section | Use of stainless- steel scoping materials | 3.606 | 0.058 | 19.200 | 0.001 |

| Use of stainless- steel storage bin | .710 | 0.399 | 7.972 | 0.047 | |

| Use of a different room for packaging | 1.405 | 0.236 | 15.771 | 0.001 | |

| Storage of the packaged flour in a cool dry place | .192 | 0.661 | 23.125 | 0.000 | |

| Storage on ranks | 1.154 | 0.283 | 13.855 | 0.003 | |

| Stored in aerated rooms | .433 | 0.511 | 9.034 | 0.029 | |

| Dispatch | Keeping records of the dispatched batches | 1.000 | 0.317 | 10.816 | 0.029 |

| section | Use of no hooks during loading | .667 | 0.414 | 13.333 | 0.010 |

| Closer of the loaded trucks to avoid rains penetration | 16.667 | 0.000 | 30.000 | 0.000 | |

The aflatoxin control practices model with the milling sub- sections as the dependent variables, HACCP knowledge and HACCP attitudes as the independent variables were significant at p< 0.001 with the management section practices, p= 0.000 packaging section practices and p= 0.007 with dispatch section practices models adjusted to their respective R-Square (R2 ) and percentage variations as shown in table 7.

Table 7: Regressions of HACCP knowledge and attitudes on aflatoxin control practices

| Aflatoxin Control Practices | R | R Square | Adjusted R Square | F | (Constant) | HACCP Knowledge | HACCP Attitude | |

| Beta | Beta | |||||||

| Management | Value | .646b | 0.417 | 0.374 | 9.649 | 12.957 | 2.167 | 0.062 |

| Sig. | .001c | 0.000 | 0.000 | 0.799 | ||||

| Raw material handling | Value | .311b | 0.097 | 0.029 | 1.443 | 19.245 | 0.573 | 0.219 |

| Sig. | .254c | 0.000 | -0.175 | 0.289 | ||||

| Milling | Value | .341b | 0.116 | 0.051 | 1.778 | 3.76 | -0.36 | 0.322 |

| Sig. | .188c | 0.000 | 0.200 | 0.079 | ||||

| Packaging | Value | .716b | 0.512 | 0.476 | 14.163 | 8.3 | 0.306 | 0.411 |

| Sig. | 0.000 | 0.000 | 0.226 | 0.000 | ||||

| Dispatch | Value | .557b | 0.31 | 0.259 | 6.068 | 6.513 | -0.113 | -0.316 |

| Sig. | .007c | 0.000 | 0.666 | 0.002 | ||||

Discussions

In Kiambu county maize milling firms, majority of the respondents were found to be men across all sections. In the raw material section, it was found to demand a lot of man power due to the majority assignment being manual which included the transport of the maize grains’ sacks in and out of the storage facilities. For quality delivery during the milling process, incorporation of male gender was part of conceptual framework development in this section. The number of the study participants with food science related education level was low therefore, it is believed that the milling process of the maize flour may have limited cautions during HACCP implementation due to insufficient knowledge. In total, only 34% of the respondents attained the university education compared to a study report that showed the respondents who attended the university were 50.5 % 23, majority of them coming from the management section therefore they had the knowhow in exercising their mandate of leading and improving the product handling team to install the aflatoxins reduction measures through HACCP installation which was found to be relatively low in this study 24. Work experience in the maize milling firm is gained while working in a similar set up for a prolonged period of time enough to gain sufficient technics and capacity particular on the food safety system backed up by the food science related course studied in the university. According to a study that was conducted elsewhere, showed that the level of the prolonged work experience has a significance correlation with the total KAP scores on food safety handling technics 25 where in this study, handlers from the packaging section were the most experienced team probably because the packaging assignment didn’t require any technical knowledge unless it was done electrically a method that was not embraced by many millers in the county.

The number of permanent employees in the maize milling firms in Kiambu County was high in management section probably because they owned the plants. As part of achieving the production of the maize flour which is free from aflatoxin, training on Food safety management systems as they are outlined in ISO 22000 to the maize and the maize flour handlers is important. By doing so, they get the clear interpretation on the relevant knowledge needed in handling, positive attitude towards the implementation of HACCP and proper gear to install the practices of aflatoxin levels reduction along the milling chain. In this study, a sufficient number of the handlers showed to have acquired the food safety training but with a disadvantage of unevenly training across all the subsection. A similar study showed a more positive number of the same which demonstrated that its attainable showing a positive association towards food safety 26 and therefore, the raw materials handling and packaging sections had the most respondents trained at 86.7% probably due to low cost of training in these sections. Un availability of food safety trained manpower has found to be a great challenge in many food industries where they only follow the directives of their supervisors but generally, they have low education level and hence training is required to be impacted to them to incorporate the HACCP principles 27.

HACCP installation knowledge is found to be enhanced through consecutive trainings. A study was conducted and showed the mean knowledge score being 77% which was higher than the one obtained from this study which was said to have been facilitated by increased training sessions on HACCP implementation 28. Kiambu county maize millers’ survey findings revealed that socioeconomic variables were significant linear predictors of HACCP knowledge where the education level was associated with increased HACCP knowledge as another study confirmed 29. Also in every food industry, knowledge has shown to impact positively on the attitude towards hazards levels in the products 30. Most of the millers in Kiambu County were inclined to agree with the requirements of HACCP. However, the management members had more positive attitude towards HACCP than all their counterparts with those working in the dispatch section showing the least favorable attitude towards HACCP. Most millers agreed that the principle of HACCP system was to prevent the hazards in the stages before the endpoint of production as indicated by the highest favorable ratings across all sections. However, they tended to disagree that HACCP is a mandatory system in Kenyan food law. With this notion, this may be the reason why their attitude towards HACCP installation in the maize milling firms with the aim of reducing aflatoxin is poor. A different study showed the satisfactorily and a positive level of attitude of the food handlers toward HACCP compared to the results of this study 31. Also, a proper approach to aflatoxin management by the management members has shown to yield a positive attitude too from the employees which is not emphasized by the Kiambu maize millers 32.

The findings of the socio-economic predictor factors of HACCP attitude linear model revealed that socioeconomic variables, Length of Service, Work Section and Food Safety Training were significant linear predictors of HACCP attitude among the maize handlers. This shows that millers with less than 5 years length of service and especially those working in the milling section were inclined to have a favorable attitude towards HACCP. It also emerged from the findings that millers who did not have food safety training had a negative attitude towards HACCP system underscoring the need for further training for the millers.

It is evident that in the management and raw material handling sections, HACCP knowledge rather than attitudes informed the practices related to aflatoxin accumulations control where in contrast, HACCP attitudes rather than knowledge influenced the practices related to aflatoxin accumulations control in the milling, packaging and dispatch sections significantly at p ≤ 0.05 according to HACCP knowledge, attitude and practices of aflatoxin reduction relationship analysis. This partly explains why despite the relatively low HACCP knowledge scores in the packaging and dispatch sections, practices related to aflatoxin accumulations control were well adhered to in the sections.

The findings also show that HACCP attitudes contributed more to aflatoxin control practices than HACCP knowledge and this could explain why the milling section had the lowest adherence to aflatoxin accumulations practices. Therefore, it is evident that more HACCP knowledge could significantly improve aflatoxin control practices. Further, inculcating the right attitudes on HACCP to the millers in all sections could significantly help to improve aflatoxin reduction practices.

During the regression analysis of HACCP knowledge, attitude and aflatoxin reduction practices, only HACCP knowledge at p = 0.000 was the significant independent variable in the model suggesting that the management practices for aflatoxin control could increase by 2.167 units when the HACCP knowledge increased by one unit. The aflatoxin control practices model with packaging practices as the dependent variable and HACCP knowledge and HACCP attitudes as the independent variables was also significant at p = 0.000 where the model could explain up to 47.6% of the variations in the packaging practices for aflatoxin control. However, only HACCP attitude was the significant independent variable in the model implying a unit change in HACCP attitude would result in an increase of 0.411 units in the packaging practices for aflatoxin control. The aflatoxin control practices model with dispatch practices as the dependent variable and HACCP knowledge and HACCP attitudes as the independent variables was significant at p = 0.007. However, only HACCP attitude was a significant independent variable at p = 0.002 and had an inverse relationship with the dependent variable in the model suggesting that the dispatch practices for aflatoxin control could decrease when the HACCP attitude increased by one unit. Therefore, a negative or poor attitude on HACCP could adversely affect the packaging practices for aflatoxin control. The study, however, failed to predict linear models for raw material handling practices and milling practices in aflatoxin control. Raw maize handling, is one of the initial stages that require proper HACCP incorporation in a maize milling chain with the effort of aflatoxin reduction. This involve the post- harvest practices required to reduce aflatoxins in the maize flour produced and has been found effective 33 which includes sorting, drying and protecting maize grains against insect infestation 34. Hand sorting has proven to be an effective way of reduction non wholesome maize grains 35. Grains drying is a critical factor for maintaining low aflatoxin levels in produced maize flour worldwide 36. Likewise, majority of the maize handlers in Kiambu County has shown to adhere to these practices effectively. Keeping the records of the quality of the dispatched maize flour that may contain aflatoxin levels beyond the thresholds to the consumers is a crucial step that enable monitoring, installation of recalling measures, decontamination or destruction of the product 37. Also, it has shown to lead to improved aflatoxin forecasting models through knowing of the contamination in advance with an aim of protecting the health risks and economic losses 38. Kiambu county maize millers have shown a relatively enlighten about the installation of these practices.

A study was conducted on the estimation of KAP to personnel who indicated that about 58% of them even didn’t know the adoption of HACCP in a food industry set up was important 39 but the maize handlers in Kiambu County showed to rise to an aggregate value of about 52% which is relative apart from the un uniform nature of its adoption across all milling sections which should be enhanced by the management section. Due to none fulltime monitoring effect, milling section showed poor adherence to practices of aflatoxin reduction which include the cross -contamination assessment within the time of milling and poor cleaning activities of the various systems of milling sections which include the cutters, de -germer and the milling rollers where studies have shown aflatoxin cross contamination 40.

Conclusions

According to the findings of this study, all the maize millers in Kiambu County require closer observation of the levels of Quality management systems instalment accessed so as to acquire the comprehensive information on the KAP of the millers within the stipulated time intervals of the validity of the permit of operation from Kenya Bureau of Standards (KEBS).

Overall, the study concludes that the practices related to aflatoxin accumulations were not well emphasized in the milling firms. HACCP attitudes rather than knowledge largely informed the practices related to aflatoxin accumulations control. Therefore, inculcating the right attitudes on HACCP to the millers in all sections could significantly help to improve aflatoxin accumulations practices.

Assessment of knowledge, attitude and practices of the maize and product handlers in Kiambu County, are key indicators of the training gaps in food safety in maize milling plants hence displaying a high level of significance of the socioeconomic variables as the linear predictors of HACCP towards aflatoxin contamination in the maize and the products. They require enough sensitization on the importance of food safety in protection of aflatoxin contamination in the end products. Good Manufacturing practices and all the pre requisite programs should be well implemented and operational throughout in the milling process. Food safety knowledge dissemination from the management section should be enhanced often to improve the product handling along the whole milling chain. KAP evaluation should be used as a tool of product handling knowledge. Other aflatoxin diagnostic strategies should be necessary so as to identify available gaps. The national government is required to improve the maize millers’ facilities though the ministry of agriculture and industrialization by ensuring that they have all requirements of safe maize flour milling from aflatoxin invasion the same time capacitated to fulfill all conditions of food safety as dictated in ISO 22000. Kiambu County is just one location in the whole country. Similar study needs to be conducted to the other 46 counties in the country. KEBS, as a standard body and the Food and Drug Act (FDA) are required to strictly take the initiative of installation of relevant knowledge, positive attitude and the enhancement of practices of aflatoxin reduction to maize millers.

Acknowledgment

The authors acknowledge the maize millers entrepreneurs who agreed to take part in this survey.

Conflicts of interest

Authors declare no conflicts of interest.

Funding sources

The authors received no financial support for the research, authorship or publication of this article.

References

- Kamano, M. H., Okoth, M. W., Kogi-Makau, W., and Kuloba, P. Knowledge, Attitude and Practices (KAP) of Farmers on Postharvest Aflatoxin Contamination of Maize in Makueni and Baringo counties, Kenya. 2021.

- World Health Organization (WHO). Aflatoxins. Food Saf. Dig. Department of Food Safety and Zoonoses. 2018; https://www.who.int/foodsafety/FSDigest_Aflatoxins_EN.pdf (accessed 01.03.2021)

- Nduti, N.N., Njeru, P.N., Mwaniki, M. and Reid, G. Aflatoxin variations in maize flour and grains collected from various regions of Kenya. African Journal of Food, Agriculture, Nutrition and Development. 2017; 17(1), pp.11743-11756. doi: 18697/ajfand.77.16875

CrossRef - Yazew, T. Therapeutic Food Development from Maize Grains, Pulses, and Cooking Banana Fruits for the Prevention of Severe Acute Malnutrition. The Scientific World Journal. 2022; https://doi.org/10.1155/2022/3547266

CrossRef - Mwalwayo, D. S., and Thole, B. Prevalence of aflatoxin and fumonisins (B1+ B2) in maize consumed in rural Malawi. Toxicology reports. 2016; 3, 173-179. https://doi.org/10.1016/j.toxrep.2016.01.010

CrossRef - Moral, J., Garcia-Lopez, M. T., Camiletti, B. X., Jaime, R., Michailides, T. J., Bandyopadhyay, R., and amp; Ortega-Beltran, A. Present status and perspective on the future use of aflatoxin biocontrol products. Agronomy. 2020; 10(4), 491. https://doi.org/10.3390/agronomy10040491

CrossRef - Feng, J., Dou, J., Wu, Z., Yin, D., and amp; Wu, W. Controlled release of biological control agents for preventing aflatoxin contamination from starch–alginate beads. Molecules. 2019; 24(10), 1858. https://doi.org/10.3390/molecules24101858

CrossRef - Waliyar F, Osiru M, Ntare BR, Vijay KKK, Sudini H, Traore A and B Diarra. Post-harvest management of aflatoxin contamination in groundnut. Special issue: Aflatoxins in maize and other crops. World Mycotoxin J. 2015; 8 (2): 245-252. https://doi.org/10.3920/WMJ2014.1766

CrossRef - Senerwa, D. M., Sirma, A. J., Mtimet, N., Kang’ethe, E. K., Grace, D., & Lindahl, J. F. Prevalence of aflatoxin in feeds and cow milk from five counties in Kenya. African Journal of Food, Agriculture, Nutrition and Development. 2016; 16(3), 11004-11021.doi: 10.18697/ajfand.75.ILRI04.

CrossRef - Frazzoli, C., Gherardi, P., Saxena, N., Belluzzi, G. and Mantovani, A. The hotspot for (global) one health in primary food production: Aflatoxin M1 in dairy products. Frontiers in public health. 2017; 4, p.294. https://doi.org/10.3389/fpubh.2016.00294

CrossRef - Rasheed, H., Xu, Y., Kimanya, M. E., Pan, X., Li, Z., Zou, X., … and amp; Gong, Y. Y. Estimating the health burden of aflatoxin attributable stunting among children in low income countries of Africa. Scientific reports. 2021; 11(1), 1-11.

CrossRef - Wanjeri, K. R., Kathenya, I. J., and amp; Obimbo, L. P. Diversity of Micro, Small and Medium Cereal Milling Enterprises in Nairobi County, Kenya and Levels of Aflatoxins in Their Milled Products. World Journal of Nutrition and Health. 2017; 5(2), 33-40. DOI: 10.12691/jnh-5-2-2

- Javanmardi, F., Khodaei, D., Sheidaei, Z., Bashiry, M., Nayebzadeh, K., Vasseghian, Y., and amp; Mousavi Khaneghah, A. Decontamination of aflatoxins in edible oils: A comprehensive review. Food Reviews International. 2022; 38(7), 1410-1426. https://doi.org/10.1080/87559129.2020.1812635

CrossRef - Williams, S. B., Baributsa, D. and Woloshuk, C. ‘Assessing Purdue Improved Crop Storage (PICS) bags to mitigate fungal growth and aflatoxin contamination’, Journal of Stored Products Research. 2014; doi: 10.1016/j.jspr.2014.08.003.

CrossRef - Rizzo, D. M., Lichtveld, M., Mazet, J. A., Togami, E., and amp; Miller, S. A. Plant health and its effects on food safety and security in a One Health framework: Four case studies. One Health Outlook. 2021; 3(1), 1-9.

CrossRef - Gachara, G., Suleiman, R., El Kadili, S., Ait Barka, E., Kilima, B., and amp; Lahlali, R. Drivers of Post-Harvest Aflatoxin Contamination: Evidence Gathered from Knowledge Disparities and Field Surveys ofMaize Farmers in the Rift Valley Region of Kenya. Toxins. 2022; 14(9), 618. https://doi.org/10.3390/toxins14090618

CrossRef - Kiambu Position and Size. Kiambu County Government. Retrieved 28 May 2020.

- Munene, A., and Hall, D. C. Factors influencing perceptions of private water quality in North America: a systematic review. Systematic Reviews. 2019; 8, 1-15.

CrossRef - Mathibu, B. M. Application of Gis in Road Classification Case Study: Kiambu County(Doctoral dissertation, University of Nairobi). 2021.

- Rahman, M. M., Chowdhury, M. R. H. K., Islam, M. A., Tohfa, M. U., Kader, M. A. L., Ahmed, A. A. A., and Donepudi, P. K. Relationship between socio-demographic characteristics and job satisfaction: evidence from private bank employees. American Journal of Trade and Policy. 2020; 7(2), 65-72. https://doi.org/10.18034/ajtp.v7i2.492

CrossRef - Geweke, J. Bayesian inference in econometric models using Monte Carlo integration. Econometrica: Journal of the Econometric Society. 1989; 1317-1339. https://doi.org/10.2307/1913710

CrossRef - Teklewold, H., Kassie, M., and Shiferaw, B. Adoption of multiple sustainable agricultural practices in rural Ethiopia. Journal of agricultural economics. 2013; 64(3), 597-623. https://doi.org/10.1111/1477-9552.12011

CrossRef - Al-Makhroumi, N., Al-Khusaibi, M., Al-Subhi, L., Al-Bulushi, I., and Al-Ruzeiqi, M. Development and validation of a food safety knowledge, attitudes and self-reported practices (KAP) questionnaire in Omani consumers. Journal of the Saudi Society of Agricultural Sciences. 2022; 21(7), 485-492. https://doi.org/10.1016/j.jssas.2022.02.001

CrossRef - Webb, M., and Morancie, A. Food safety knowledge of foodservice workers at a university campus by education level, experience, and food safety training. Food control. 2015; 50, 259-264. https://doi.org/10.1016/j.foodcont.2014.09.002.

CrossRef - Jubayer, M. F., Kayshar, M. S., Kabir, M. F., Arifin, M. S., MT, I. L., Uddin, M. N., and Al-Emran, M. Current state of COVID-19 knowledge, attitude, practices, and associated factors among Bangladeshi food handlers from various food industries. 2021; DOI: 1101/2021.01.06.21249118

CrossRef - Aslam, M., Malik, M. I., and Kausar, S. Effect of food safety and hygiene training on KAP score among food handlers in multiple food service institution, Pakistan. Journal of Food Safety and Hygiene. 2021; 7(2), 86-96. https://doi.org/10.18502/jfsh.v7i2.8400

CrossRef - Khan, S. A., Ahmad, S.,and Jamshed, M. Role of skill India initiative in Indian food processing industries. Economic Affairs. 2019; 64(1), 77-84. http://doi.org/30954/0424-2513.1.2019.10

CrossRef - Hassan, S. H. M. A. The Impact of Knowledge, Attitudes and Practices of Food Handlers towards HACCP at Five Stars Hotels in Dubai, United Arab Emirates. 2015; (Doctoral dissertation, University of Gezira). http://repo.uofg.edu.sd/handle/123456789/5330

- Rugarabamu, S., Ibrahim, M., and Byanaku, A. Knowledge, attitudes, and practices (KAP) towards COVID-19: A quick online cross-sectional survey among Tanzanian residents. MedRxiv. 2020; https://doi.org/10.1101/2020.04.26.20080820

CrossRef - Kwol, V. S., Eluwole, K. K., Avci, T., and Lasisi, T. T. Another look into the Knowledge Attitude Practice (KAP) model for food control: An investigation of the mediating role of food handlers’ attitudes. Food control. 2020; 110, 107025.

CrossRef - Rabori, M. M., Avazpour, M., Eskandarinasab, M., and Khalooei, A. Food safety knowledge, attitude, and practice among restaurant food handlers in Kerman, Iran. Journal of Environmental Treatment Techniques. 2020; 8(1), 535-539. http:/www.jett.dormaj.com.

- Da Cunha, D. T. Improving food safety practices in the foodservice industry. Current Opinion in Food Science. 2021; 42, 127-133. https://doi.org/10.1016/j.cofs.2021.05.010

CrossRef - Negash, D. A review of aflatoxin: occurrence, prevention, and gaps in both food and feed safety. Journal of Applied Microbiological Research. 2018; 1(1), 35-43.

CrossRef - Kamala, A., Kimanya, M., Haesaert, G., Tiisekwa, B., Madege, R., Degraeve, S., and De Meulenaer, B. Local post-harvest practices associated with aflatoxin and fumonisin contamination of maize in three agro ecological zones of Tanzania. Food Additives and Contaminants. 2016; Part A, 33(3), 551-559. https://doi.org/10.1080/19440049.2016.1138546

CrossRef - Matumba, L., Van Poucke, C., Njumbe Ediage, E., Jacobs, B., and De Saeger, S. Effectiveness of hand sorting, flotation/washing, dehulling and combinations thereof on the decontamination of mycotoxin-contaminated white maize. Food Additives and Contaminants. 2015; Part A, 32(6), 960-969. https://doi.org/10.1080/19440049.2015.1029535

CrossRef - Bradford, K. J., Dahal, P., Van Asbrouck, J., Kunusoth, K., Bello, P., Thompson, J., and Wu, F. The dry chain: Reducing postharvest losses and improving food safety in humid climates. In Food Industry Wastes. 2020; (pp. 375-389). Academic Press.https://doi.org/10.1016/B978-0-12-817121-9.00017-6

CrossRef - Herrman, T. J., Hoffmann, V., Kamaraba, I., and Konlambigue, M. Mitigating aflatoxin in Rwanda. Journal of Regulatory Science. 2022; https://doi.org/10.21423/jrs-v09i2kamaraba. https://doi.org/10.1016/j.foodcont.2019.107025

CrossRef - Liu, N., Liu, C., Dudaš, T. N., Loc, M. Č., Bagi, F. F., and Van der Fels-Klerx, H. J. Improved aflatoxins and fumonisins forecasting models for maize (PREMA and PREFUM), using combined mechanistic and Bayesian Network modeling—Serbia as a case study. Frontiers in Microbiology. 2021; 12, 643604. https://doi.org/10.3389/fmicb.2021.643604

CrossRef - Ahmed, M. A. B., Abdelgadir, A. A., and Ismail, H. M. Estimation of Knowledge, Attitude, and Practice Related (KAP) to Biosecurity Measures and Hazard Analysis Critical Control Point (HACCP) Prerequisites in Poultry Meat Production in Khartoum State, Sudan. Journal of Animal Sciences and Livestock Production. 2021; 5(5), 1-5: https://www.imedpub.com/

CrossRef - Sabillón, L., Stratton, J., Rose, D., and Bianchini, A. Microbiological survey of equipment and wheat‐milled fractions of a milling operation. Cereal Chemistry. 2021; 98(1), 44-51. https://doi.org/10.1002/cche.10373

CrossRef