Introduction

India is the world’s largest producer of banana.1 Occupying about 13% of the total area under fruits in India, banana is grown almost in every state. Banana plant is known as the largest herbaceous flowering plant in the world. The banana inflorescence is an elongated, oval shaped, dark purple bud.2 Banana blossom or banana heart is an agricultural by-product, which is obtained from the subtropical Musa species. It is produced on the banana stem of a banana tree. Generally each banana stem has a single banana flower but in some cases there are more than one. The banana fruits develop from the banana blossom. Once the banana fruits start to develop, the banana flower could be cut few inches from the fruit cluster using a sharp knife. Banana blossom is considered as vegetable and is cooked in a variety of dishes in India, Sri Lanka and South East Asian countries 3 in the form of curry, deep fried, cutlet etc. Banana flower has a typical taste i.e., crunchy, nutty, and starchy.4 The colour of the banana blossom ranges from orange to purple and the florets inside are either white or pale yellow in colour. Banana blossoms are showy and spring flowering. Banana blossom is rich in nutrients and antioxidants reported to have several health benefits. Banana blossom is an excellent source of fibre to the human diet.5 The extract from the flower is believed to inhibit the growth of pathogenic bacteria as well as malarial bacterial growth. The extract also stabilises the blood sugar levels which is good for the diabetics.6 Banana blossom helps to fight anaemia and also relieves menstrual problems in women. It also relieves anxiety. The banana blossom has been used to treat ailments including heart pain, asthma and diarrhoea.7

Although banana blossom has a tremendous nutritional value, it is perishable due to the high moisture present and hence has a very short shelf life.5 Food processing techniques are meant to stabilize the products and lengthen their storage and shelf life. In the present days, convenience foods are gaining popularity in the urban markets. Banana blossom need to be cleaned well before they are cooked as a vegetable. Cleaning of banana blossom is a tedious process. Initially the tough external sheath or bract is removed one by one. The bunch of florets present in each bract is collected. Again the floret is opened where in the style resembling a match stick and outermost petal (sepal) are removed. The process is repeated for each floret. The above method of cleaning involves more time and also causes staining in hands. Due to the tedious process involved in cleaning, to cut down the preparation time, banana blossom can be preserved and used.8

The intake of banana blossom in diet of urban people is found to be diminishing due to the busy lifestyle. Fresh fruits and vegetables are good examples of convenient foods.9 In the present days, convenience food are welcomed by the Indian households due to the less time spent by working women in the kitchen.10 Minimal processing of fresh products could be employed to maintain the fresh like characteristics and also provide the convenience demanded by consumers. The consuming attribute of a consumer depends upon the nutritional value, simplicity, safety, and convenience. Minimal processing aids in quick and easy preparation of ready meals.9 The growing demand for freshly processed food with the guarantee of safety has urged those in research to focus on studying new ways of extending the shelf life of fresh-cut produce.11 The banana florets have a very short shelf life due higher moisture content and also more prone to enzymatic browning.5, 12 Hence this study aimed to develop a ready to cook banana blossom and to evaluate its’ shelf life as a freshly processed product.

Materials and Method

Raw material and sample preparation

Freshly harvested Banana blossoms of Nendran variety were procured from a local vegetable market at Coimbatore, Tamil Nadu. The blossom was purple in colour and each blossom weighed 850 g. The weight of florets in a blossom was found to be 250 g.

The outer sheaths or bracts were removed manually and discarded. The florets were then cleaned to remove the style and the sepal using a hand tool, made up of stainless steel provided with a plastic handle.

Packaging materials

Packaging materials of different thickness and variety (LDPE 110 micron), Polypropylene (40 micron), Polypropylene (60 micron) and Polypropylene (70 micron) were purchased from the local market.

Package ventilation (%)

The number of vents on each packet was determined based on the area of packaging material and diameter of vent. In this study, the packaging bags were ventilated with 2 holes of 5mm dia. and also in another set they were micro perforated.

Pre treatment

Banana florets are more prone to browning when exposed to atmospheric condition. The formation of brown pigments is developed when PPO (poly phenol oxidase enzyme) reacts with phenolic compounds. Hence in order to arrest browning, the cleaned florets were dipped in 0.2 % citric acid solution for 30 minutes.12

Fresh processing of banana blossom

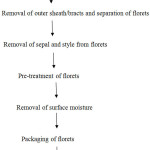

The flow chart below depicts the steps involved in processing banana florets in their fresh form.

|

Chart 1 |

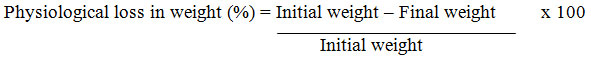

Physiological Weight Loss

The packaged florets were weighed with an electronic balance (BL 220H model) of 0.01 g accuracy every day during storage. The initial and final weight of the florets was recorded and the percentage loss in weight was calculated as given below.

Quality evaluation based on sensory scores

The quality aspects of minimally processed products play an important role in marketing and securing consumer acceptance. Sensory liking contributes to the freshness and organoleptic characteristics of minimally processed products.10

The main quality losses that could occur in freshly processed banana florets during storage are changes in colour (browning), texture (loss of firmness) and appearance (loss of succulence). In consequence, it is important to establish how these factors affect acceptance and preference of freshly processed vegetables by the consumers. The sensory analysis was carried out based on a descriptive test on the qualities of florets viz., colour, texture, appearance based on the grid of sensory attributes developed for minimally processed herbs13 as a model for the study (Table 1).

Table 1: Quality attributes of banana florets with description and scores

| Colour | Characteristics | Description | Scores |

| Fresh Pale yellow | Characteristic color of fresh florets | 5 | |

| Dull yellowness | Some of the color lost, but considered relatively fresh | 4 | |

| Dull yellow with onset of browning | Untypical for fresh florets | 3 | |

| Majority browning | First signs of spoilage | 2 | |

| Majority browning | Spoilage has started | 1 | |

| Texture | Firm | Firm and fresh | 5 |

| Firm | Considered relatively fresh | 4 | |

| Slightly Soft | Slightly wilted and losing firmness | 3 | |

| Soft | Wilted, first signs of spoilage | 2 | |

| Very Soft | First signs of spoilage | 1 | |

| Appearance | |||

| Fresh and succulent | Fresh and juicy, characteristicof fresh florets | 5 | |

| Relatively fresh and succulent | Canstill be considered relative fresh | 4 | |

| Less succulent and less fresh | Almost all succulence and fresh appearance lost | 3 | |

| Very less succulent | Beginning to dry | 2 | |

| Rather dry | Dried | 1 | |

Scores: 5 – Very good; 4- Good; 3-Average; 2-Poor; 1-Very poor

Statistical analysis

Effect of different parameters of packaging was carried out by Statistical Analysis. Analysis of variance (ANOVA) was conducted using Completely Randomised Block Design (CRD) using the statistical software, AGRES based on the effect of packaging treatment on the Physiological weight loss of the sample. All the treatments were replicated three times.

Results and Discussion

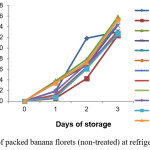

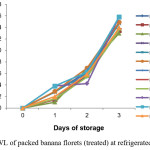

Effect of packaging on PWL of banana florets under ambient storage

Physiological Weight Loss (PWL) influences the quality of stored fruits and vegetables and is a major reason for deterioration during storage.14 The physiological loss in weight of banana florets under different packaging treatments was studied and is presented in fig. 1-4. It could be seen that the PWL of samples were found to be increasing on the progression of storage. There was significant difference (P<0.05) for the individual samples during days of storage. The highest PWL (15.28%) at ambient storage was recorded for PP 70 micron thickness with micro perforations without any treatment (control) at the end of storage (Fig.1). Similarly lowest PWL (13.4 & 13.78%) was recorded for the samples packed in 110 micron thickness PE bag with micro perforations and 40 micron thickness PP with 2 vents at the same conditions of storage. Minimum weight loss was observed for leafy vegetables when stored in perforated polythene bags.15 The PWL was found to be high for those samples packed in non-ventilated packages. In order to arrest the browning of banana florets, the same was dipped in citric acid solution of known concentration. The packaging materials and pre-treatment of banana florets had an effect on the PWL. Similar results were observed for pre-treated and control tomatoes stored at refrigerated and room conditions.16 The pre-treated banana florets exhibited less PWL than the control. The lowest PWL (12.2%) was observed for the sample packed in 110 micron, micro perforated PE bag (Fig. 2). The results of the study revealed that, there was no significant difference among the treatments.

|

Figure 1: PWL of packed banana florets (non-treated) at ambient storage Click here to View figure |

|

Figure 2: PWL of packed banana florets (pre-treated) at ambient storage Click here to View figure |

Effect of packaging on PWL of banana florets under refrigerated storage

Physiological Weight Loss was in a slower phase under refrigerated condition as seen from the fig. 3, 4. This may be due to reduced respiration rate and lower difference of relative humidity between the sample and the storage atmosphere. However, on the third day of storage, there was no significant difference among the treatments both at ambient and refrigerated condition. Performance of polyethylene bag was found to be better in terms of less weight loss compared to polypropylene bag for the untreated samples at the end of storage (Fig. 3). This may be due to the high barrier property of polyethylene bag for moisture thereby preventing loss of moisture through transpiration. Similar findings were reported for vegetables (chilli, tomato, carrot etc.) stored at refrigerated condition.17 The PWL was found to be minimum (12.4 %) in non perforated 110 micron PE bag at the end of storage for the untreated sample (Fig. 3). The physiological weight loss of treated samples was less than the untreated samples (Fig. 4).

|

Figure 3: PWL of packed banana florets (non-treated) at refrigerated storage Click here to View figure |

|

Figure 4: PWL of packed banana florets (treated) at refrigerated storage Click here to View figure |

Effect of packaging treatment and storage condition on the shelf life of banana florets

The shelf life of fruits and vegetables is largely depicted from the determination of sensory parameters.10 Considering the deterioration in quality by subjective evaluation, the shelf life of the stored samples was assessed for both untreated and treated florets (Tables 1,2). According to the results recorded in table 3, the untreated banana florets packed and stored in different materials retained their freshness as seen by the quality attributes for two days. However, variation in quality was observed on the third day for all the samples. The banana florets untreated and stored at ambient condition, remained edible suitable for marketing based on the quality scores for non perforated PP bag of 40 micron thickness. There was no significant change in the sample under refrigerated storage. The results were similar for the same packaging material under refrigerated condition. Polypropylene bags of 38 micron gave best results for extending shelf life of curry leaves under ambient condition.18 The remaining samples lost their colour to brown, wilted and dry at the end of storage and were not found suitable for consumption. Higher packaging material thickness and venting resulted in quicker deterioration in quality after 2 days. Quality scores were recorded for the samples treated and stored under ambient and refrigerated condition (Table 2). The pre -treated samples in different packaging materials stayed fresh for 2 days. There was no significance difference among the packaging treatments. The samples packed in different packaging materials and stored under refrigerated condition was not found to be acceptable after two days storage. This may be due to the high initial moisture present in the sample which results in undesirable physiological changes when exposed to low temperature. In other words, banana florets were susceptible to chilling injury when stored at low temperature. Even after pre treatment, studies on cabbage and cauliflower revealed spoilage after 12 days of storage under refrigerated condition.19

|

Table 1: Quality attributes of banana florets (untreated) at ambient and refrigerated storage Click here to View table |

|

Table 2: Quality attributes of banana florets (treated) at ambient and refrigerated storage Click here to View table |

Conclusion

The florets inside banana blossom are consumed as a vegetable in South East Asian countries. Cleaning of the blossom is a cumbersome process. The banana florets could stay fresh for few hours only when kept under open atmosphere since they are more prone to enzymatic browning. The study aimed in improving the shelf life of the cleaned banana blossom which could be marketed as a ready to use product. The results of the study revealed that the banana florets could remain fresh for 3 days when packed in non ventilated poly propylene 40 micron bag both under ambient and refrigerated storage.

Acknowledgements

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

References

- NHB. Database National Horticulture Board. Ministry of Agriculture, Government of India. 2009.

- Gunavathy N., Padmavathy S., Murugavel S. C. Phytochemical Evaluation of Musa Acuminata Bract using screening, FTIR and UV-VIS Spectroscopic Analysis. Journal of International Academic Research for Multidisciplinary. 2014;2(1):212-221.

- Sharmila and Puraikalan Y. Development and Evaluation of Banana Blossom Incorporated Dark Chocolate. International Journal of Science and Research. 2015;4:1409-1411.

- Catherine Reddy. All about banana flower.http://theindianvegan.blogspot.in/2012/09/all-about-banana-flower.html

- Sheng Zhan-Wu, Ma Wei-Hong, Jin Zhi-Qiang, Bi Yang, Sun Zhi-Gao, Dou Hua-Ting, Gao Jin-He, Li Jing-Yang, Han Li-Na. Investigation of dietary fiber, protein, vitamin E and other nutritional compounds of banana flower of two cultivars grown in China. African Journal of Biotechnology. 2010;925:3888-3895.

- Shamala Pulugutha. What are the benefits of banana flower. https://www.livestrong.com/article/401844-what-are-the-benefits-of-banana-flowers/2017.

- Sumathy V., Lachumy S., Zakaria Z., Sasidharan S. In vitro bioactivity and phytochemical screening of Musa acuminata flower. Pharmacologyonline. 2011;118-217.

- Singh S. “Banana blossom-an understated food with high functional benefits. International Journal of Current Research. 2017;9(01):44516-44519.

- Bansal V., Siddiqui M., Rahman M. Minimally Processed Foods: Overview, in Minimally Processed Foods. M. W. Siddiqui and M. S. Rahman Eds. ed New York: Springer International Publishing. 2015;1-15.

- Corbo M. R., Speranza B., Campaniello D., D’Amato D., Sinigaglia M. Fresh-cut fruits preservation: current status and emerging technologies. In V. Méndez (Ed.), Current research technology and education topic in applied microbiology and microbial biotechnology. 2010;1143-1154.

- Srinivasan S., Shende K. M. A study on the benefits of convenience food to working women. Atithya: A Journal of Hospitality. 2015;1(1):43-50.

- Giorgiana M. C., Maria T., Crina M., Adriana D., Sorin S. Sensory Evaluation of Minimally Processed Parsley (Petroselinum crispum), Dill (Anethum graveolens) and Lovage (Levisticum officinale) Stored at Refrigeration Temperatures. Bulletin UASVM Agriculture. 2012;69:1843-5386.

- Cecilia N. N., Jeane Pierre Emond. Relationship between weight loss and visual quality of fruits and vegetables. Proc. Fl. State Hort. Soc. 2007;120:235-245.

- Yeole S. N., Harode S. M., Nadre R. G. Effect of storage and prepackaging on keeping quality of vegetables. Asian J. Home Sci. 2009;3(2):186-189.

- Workneh T. S., Osthoff G., Steyn M. Effects of preharvest treatment, disinfections, packaging and storage environment on quality of tomato. Journal of Food Science and Technology. 2012;49(6):685-694.

CrossRef - Vijaya V., Koraddi and Devendrappa S. Analysis of physiological loss of weight of vegetables under refrigerated conditions. Journal of Farm Sciences. 2011;1(1):61-68.

- Dawn C.P. Ambrose Annamalai S.J.K and Ravindra Naik. Effect of packaging in extending shelf life of curry leaves. Journal of Applied Horticulture. 2015;17(2):165-168.

- Kanchana S. Wickramarachchi and Senaratne L. Ranamukhaarachchi. Preservation of Fiber-Rich Banana Blossom as a Dehydrated Vegetable. Science Asia. 2005;31:265-271.

CrossRef - Jany M.N.H, Sarker C, Mazumder M.A.R. and Shikder M.F.H. Effect of storage conditions on quality and shelf life of selected winter vegetables. J. Bangladesh Agril. Univ. 2008;6(2):391–400.