Introduction

Drying is an excellent way to preserve food and open sun drying is the oldest agricultural practice to preserve food.1 The moisture content in fresh produce is the basic cause for spoilage and if water is removed then the shelf life of production increases. Removal of water results in a reduction of weight and volume of the product, thereby reducing the cost and facilitating easy transportation. Drying is a unit operation widely followed under value addition.2,3 Since drying is a cost-intensive operation, use of solar energy is preferable as it is a non-exhaustive and eco-friendly practice.4 Traditional sun drying is the oldest method often resulting in poor quality produce, as the product is not protected against wind, rodents, dust, rain, bird etc also drying process is not controllable requiring more drying space and labor.5,6 Direct sunlight results in loss of color as well as the flavor of the product and it becomes undesirable.7 Solar dryers are the best alternatives to traditional drying because mechanical drying is not affordable by small farmers.8,9

Natural convection solar dryers successfully reduce the post-harvest losses.10 Natural convection solar tunnel dryer was invented and tested by the Institute for Agricultural Engineering, Hohenheim University, Germany.11 The same design was also tested by a lot of other researchers in their geographic conditions and found that solar tunnel dryer conserves a lot of energy.12,13 A little modification was done in the tunnel dryer to minimise the heat losses as tested by the Maharana Pratap University of Agriculture and Technology (MPUAT), Udaipur, (27 420 N, 75 330 E) Rajasthan, India.2 Large-scale and controlled drying is possible in a solar tunnel dryer. It is large enough to allow a person to enter and carry out various operations. The orientation of tunnel solar dryer should be in an east-west direction to minimise the heat losses and ultraviolet stabilized polycarbonate/polyethylene sheet of 200-micron size is mostly used as a cover material.14 Keeping in view of the above-mentioned aspects, this study is done to evaluate the performance of solar tunnel dryer for around the year use for drying of fruits and vegetables.

Material and Method

Raw material

According to the seasonal availability, four products (garlic, chili, fenugreek leaves and aonla candy) were selected for the drying purpose in a solar tunnel dryer.

Sample Preparation for drying

Garlic

Freshly harvested of garlic was procured from the university farm of CCSHAU, Hisar during the month of June. The garlic was then cleaned manually and unwanted material like straw and dust were removed. After weighing bulbs were broken into cloves using a garlic bulb breaking machine . The loose ‘papery shell” was removed by aspiration.

Chilli

Chillies were cleaned manually and unwanted materials were removed. After cleaning total quantity was graded into three groups according to their condition and color. Starting weight and moisture content of all the samples were recorded One lot of the sample was subjected to chemical treatment by blanching using hot water at 90⁰C for 3 minutes and then cooled in cold water and drained on a perforated tray. The samples were then loaded in solar tunnel dryer for drying.

Fenugreek

Fresh, matured fenugreek was procured from local market of Hisar during the month of January. The fenugreek was cleaned manually after cleaning it was stalked. The weight of the cleaned one and initial moisture content of fenugreek was recorded before drying.

Aonla candy

The fractionated portions or slices left after making aonla murabba were used for candy making by soaking in 75% sugar syrup for three days. These slices were procured from market. The sugar treated slices were loaded in solar tunnel dryer for drying.

Drying

After preparation, samples were kept in solar tunnel dryer during the month of their availability. A unique versatile and low-cost Solar Tunnel Dryer was developed at MPUAT, Udaipur. Realizing the importance of solar tunnel dryer for value addition and processing of products a similar dryer with a floor area of 10m × 3.75m was installed at Hisar to evaluate its performance in ambient conditions of Haryana. It consists of a semi-cylindrical metallic frame covered with UV stabilized transparent polyethylene sheet of 200-micron thickness, five chimneys on the top, two exhaust fan and five vents towards the bottom remove the moist air, insulated wall on north side and the floor was painted black. It consists of 64 trays for loading of material. The average temperature inside the tunnel was 10-20⁰C higher than the ambient temperature. The dimensions and other parameters of solar tunnel dryer are given in table 1. After loading various parameters which were required for analysis and temperature was recorded at 2 h interval during drying.

Table 1: Discription of STD

| Parameter |

Specifications |

| Length of solar tunnel dryer |

10 m |

| Width of solar tunnel dryer |

3.75 m |

| Ceiling height |

1.98 m |

| Dimensions of tray |

.81 * .73 m2 |

| Flooring height |

.19 m |

Performance evaluation of solar tunnel dryer

Performance of the solar tunnel dryer was evaluated at no load and full load condition for garlic, chili, fenugreek and aonla candy. Various parameters were recorded during the process

- Solar insolation: solar insolation was measured by using suryamapi in mW/cm2

- Ambient temperature: it was measured by using mercury thermometer.

- Dryer temperature at different points: twelve thermometers were placed at different positions inside tunnel.

Moisture Content

The starting and final moisture content of samples were determined by the AOAC method.15 About 10 to 20g samples was taken and kept in the oven at 80°C. Final weight was taken after attaining constant weight and moisture content.

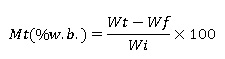

The subsequent moisture content of the samples during the drying period were calculated by weight reduction method after a regular interval of time using the formula:

Here, Mt= Moisture Content at time t

Wt= Weight of sample at time t

Wf= Weight of oven dry sample

Wi= Initial weight of sample

Drying rate

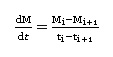

Drying rate is weight of water removed per unit time by using the formula16:

Where,

dm/dt= Drying rate, percent moisture loss per hour

Mi = M.C. (% wb) of sample at time ti

Mi+1= M.C. (% wb) of sample at time ti+1

Thermal efficiency of STD

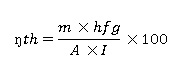

Thermal efficiency of the solar tunnel drier was estimated using the formula17:

Where,

ŋth = drier thermal efficiency

m = the mass of water evaporated in time t = (mi – mi) kg

hfg = the latent heat of vaporization of water(kJ/kg)

A = the area of solar tunnel drier in m2

I = the solar intensity in W/m2.

Sensory evaluation

Sensory evaluation of organoleptic properties of dried products was carried out by panel of ten judges of different age group and sex based on ‘9’ point Hedonic scale.18

Result and Discussion

No Load Testing

No load testing was done for finding temperature status at different places in a solar tunnel dryer. The testing on no load conditions of the dryer was done for three different season’s summer, rainy and during winter season. Table.2 shows insolation and temperature variation inside and outside the dryer. Mohod et al. (2011)[19] and Singh et al. (2006)20 reported similar results at no load conditions.

Table 2: Variation of temperature and insolation during different seasons at no load conditions.

|

Month |

Ambient temperature ⁰C |

Temperature inside STD ⁰C |

Insolation, W/m2 |

|

May (summer) |

(29-44) |

(34-60) |

(440-820) |

|

July (rainy) |

(19-33) |

(30-50) |

(50-620) |

|

December (winter) |

(16-29) |

(28-48.5) |

(80-640) |

Performance evaluation at full load conditions

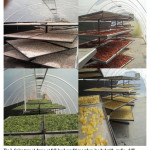

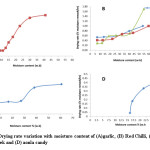

Performance of the solar tunnel dryer was evaluated for the drying of garlic, chili, fenugreek and aonla candy according to their availability. Table 3 gives the details of starting and final moisture content. It took 4-8 days for drying the products. The temperature within the tunnel was always higher than the starting conditions. Fig 1 shows solar tunnel dryer at full load conditions. The temperature inside the dryer was optimum for drying. The Higher temperature is not good for some food products as Vega-Galvez et al. (2008)21 and Turhan et al. (1997)22 suggested that using temperature above 70⁰C for drying results in a dark brown color due non-enzymatic browning reaction for the red pepper. Drying rate versus moisture content during solar tunnel drying of garlic, chilli, fenugreek and aonla candy is shown in Fig. 2. It is evident from the figure that drying rate was higher at higher moisture content and it decreased as moisture content decreased. At the starting stage of drying moisture content was high and more moisture was evaporated from the outer surface. As the drying process continued, the free moisture available on the surface decreased and less evaporation takes place and hence drying rate significantly decreased with drying time as well as moisture content.

The relationship between rate of drying and moisture content gives following regression equations.

Garlic

y = -0.000x2 + 0.036x – 0.347 R² = 0.978

fenugreek

y = 2E-05x2 + 0.012x + 0.251 R² = 0.853

Red Chilli

For grade 1

y = 0.000x2 + 0.003x + 0.371 R² = 0.974

For grade 2

y = 0.000x2 – 0.012x + 0.414 R² = 0.918

For grade 3

y = 0.000x2 – 0.003x + 0.548 R² = 0.988

Aonla candy

y = -0.002x2 + 0.151x – 1.649 R² = 0.963

In general, it was found that the drying took place in the falling rate period and the constant rate period was absent for all the products. Falling rate period indicates diffusion. Similar conclusions have been reported for drying studies onion slices.23 The coefficient of correlation was more than 0.80 for all the experimental conditions that revealed the good correlation.24

Table 3: Drying test results in solar tunnel dryer at full load conditions.

|

Month |

Product |

Initial Moisture content % (w.b) |

Final Moisture content % (w.b) |

Drying time (days) |

Ambient temperature ⁰C |

Temperature inside STD ⁰C |

Insolation, W/m2 |

|

June |

Garlic |

60- 70 |

8 – 9 |

8 |

(34-44) |

(45-62) |

(500-990) |

|

October |

Chilli |

77-79 |

7 |

6-7 |

(28-37) |

(37-60) |

(280-880) |

|

January |

Fenugreek |

86 |

7.2 |

5 |

(15-25) |

(21-50) |

(100-680) |

|

March |

Aonla candy |

44 |

16 |

4 |

(33-40) |

(41-61) |

(320-940) |

|

Figure 1: Solar tunnel dryer at full load conditions when loaded with garlic, chilli, fenugreek and aonla candy. Click here to View figure |

|

Figure 2: Drying rate variation with moisture content of (A)garlic, (B) Red Chilli, (C) fenugreek and (D) aonla candy Click here to View figure |

Sensory Evaluation

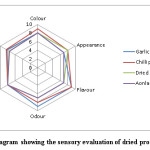

The average values of results of sensory evaluation by 30 panelists using 9- point Hedonic scale in terms of color, appearance, flavor, odor, taste and overall acceptance is given in Fig 3. The evaluation shows that the dried products were of good quality and highly acceptable. It is found that chili powder shows highest overall acceptability. Similar results were reported by Janjai et al., (2009),4 who reported that solar drying increases the overall acceptability and shelf life of products.

|

Figure 3: Radar diagram showing the sensory evaluation of dried products. Click here to View figure |

Thermal Efficiency of Solar Tunnel Dryer

The overall thermal efficiency of STD was calculated for all the drying cycles. During the initial days of drying the dryer had a higher efficiency as compared to the following days. This was due to starting stage of drying, a higher amount of water was evaporated. Table 4 shows the average thermal efficiency of STD during drying of different products. Chavan et al. (2011)25 found that overall drying efficiency of the STD is about 19.87% for mackerel drying.

Table 4: Average thermal efficiency of STD.

|

Product |

MW (mass of water evaporated) kg |

I (average Insolation) W/m2 |

drier thermal efficiency% |

|

Garlic |

161 |

721 |

13.45 |

|

Chilli |

112 |

551 |

12.25 |

|

Fenugreek |

81 |

400 |

16.27 |

|

Aonla candy |

196 |

600 |

14 |

Conclusion

Natural convection solar tunnel dryer was capable of drying garlic, chilli, fenugreek and aonla candy from starting moisture content to the final moisture content which is considered to be safe in less than 8 days. Products dried in solar tunnel dryer were hygienic and their sensory evaluation shows that they are of good quality and highly acceptable. The maximum temperature inside the tunnel dryer was 50⁰C while the minimum was 21⁰C in the typical day of the January against the ambient temperature of 25⁰C and 15⁰C respectively. Average thermal efficiency was found between 8.89% to 17.63%. So, solar tunnel dryer can be utilized for drying highly perishable vegetables and fruits which could increase the income of farmers with little maintenance.

Acknowledgements

The author appreciates the help and support received in the form of guidance and money from the faculty and staff of college of Agricultural engineering and technology, CCSHAU, Hisar,India.

References

- Whitfield, D. E. “Solar Dryer Systems, and the Internet: Important resources to improve food preparation.” International conference on solar cooking, Kimberly, South Africa. 2000.

- Rathore, N. S., and N. L. Panwar. “Experimental studies on hemi cylindrical walk-in type solar tunnel dryer for grape drying.” Applied Energy. 2010;87(8):2764-2767.

CrossRef - Ng, Ah Bing, and Shiming Deng. “A new termination control method for a clothes drying process in a clothes dryer.” Applied Energy. 2008;85(9):818-829.

CrossRef - Janjai, S., et al. “Experimental and simulated performance of a PV-ventilated solar greenhouse dryer for drying of peeled longan and banana.” Solar Energy. 2009;83(9):1550-1565.

CrossRef - Jain, Dilip, and Pankaj B. Pathare. “Study the drying kinetics of open sun drying of fish.” Journal of Food Engineering. 2007;78(4):1315-1319.

CrossRef - Purohit, Pallav, Atul Kumar, and Tara Chandra Kandpal. “Solar drying vs. open sun drying: A framework for financial evaluation.” Solar Energy. 2006;80(12):1568-1579.

CrossRef - Jayaraman, K. S., DK Das Gupta, and N. Babu Rao. “Quality characteristics of some vegetables dried by direct and indirect sun drying.” Indian food packer. 1991;45(1):16-23.

- Muhlbauer, W., Esper, A. Muller, J. Solar energy in agriculture. ISES Solar World Congress, Budapest. 1993;23–27.

- Hossain, M. A., and B. K. Bala. “Drying of hot chilli using solar tunnel drier.” Solar Energy. 2007;81(1):85-92.

CrossRef - Forson FK, Nazha MAA, Akuffo FO. Natural convection solar crop dryers of commercial scale in Ghana: design, construction and performance. Ambient Energy. 1996;17:123–30.

CrossRef - Lutz K, Muhlbauer W. Solar tunnel dryer with integrated collector. Drying Technol. 1986;4:583–603.

CrossRef - Farhat A, Kooli S, Kerkeni C, Maalej M, Fadhel A, Belghith A. Validation of a pepper drying model in polyethylene tunnel greenhouse. Int J Therm Sci. 2004;43:53–8.

CrossRef - Garg HP, Kumar R. Studies on semi-cylindrical solar tunnel dryers: year round collector performance. Int J Energy Res. 1998;22:1381–95.

CrossRef - Singh, H. P., Surender S. Dhankhar, and K. K. Dahiya. Horticultural crops. Stadium Press (India) Pvt Limited. 2009.

- AOAC (2006) Official methods of analysis and calculations moisture (M) Method 934.06 Fruits, Vegetables, and their Products, Association of Analytical Communities, Gaithersburg.

- Wankhade, P. K., R. S. Sapkal, and V. S. Sapkal. “Drying characteristics of okra slices using different drying methods by comparative evaluation.” Proceedings of the world congress on engineering and computer science. 2012;2.

- Ayyappan, S., and K. Mayilsamy. “Experimental investigation on a solar tunnel drier for copra drying.” 2010.

- Amerine, M., Pangborn, R.M., Roessler, E.B., 1965. Principles of Sensory Evaluation of Food. Academic Press, New York, USA.

- Mohod, A.G., Sengar, S.H. and Khandetod, Y.P.Solar tunnel dryer as an income gereration unit for fisherman bioinfo renewable & sustainable energy. 2011;1(1)01-04.

- Singh, Pratap, N. S. Rathore, and A. N. Mathur. “Development of solar tunnel dryer for industrial use.” Journal of Agricultural Engineering. 2007;44(1):92-95.

- Vega-Galvez, A., Lemus-Mondaca, R., Bilbao-Sainz, C., Fito, P. and Andres, A. Effect of air drying temperature on the quality of rehydrated dried red bell pepper. Journal of Food Engineering. 2008;85:42-50.

CrossRef - TURHAN, MAHIR, K. NAZAN TURHAN, and Ferhunde Sahbaz. “Drying kinetics of red pepper.” Journal of food processing and preservation. 1997;21(3):209-223.

CrossRef - Rapusas, R. S., and R. H. Driscoll. “The Thin-layer drying characterstics of white onion slices.” Drying Technology. 1995;13(8)-9:1905-1931.

- Revaskar, Vithhal, et al. “Drying behaviour and energy requirement for dehydration of white onion slices.” International Journal of Food Engineering 2007;3:5.

- Chavan, B. R., A. Yakupitiyage, and S. Kumar. “Drying performance, quality characteristics, and financial evaluation of Indian Mackerel (Rastrilliger kangurta) dried by a solar tunnel dryer.” Thammasat International Journal of Science and Technology. 2011;16(2):11-25.