Introduction

Senna or Sonamukhi botanically known as Cassia angustifolia Vahl., is native to Saudi Arabia. It is commonly known as “Tinnevelly Senna”. It was first introduced in Tirunelvelly district of Tamil Nadu in mid eighteenth century from European countries and hence the Indian produce as a whole is called Tinnevelly Senna. The leaves and the pods are the economical parts, containing sennosides A, B, C & D which are responsible for its laxative properties. The leaves are used as an ingredient of herbal tea in Europe. India is the largest producer and exporter of Senna in the world. Nearly 75 per cent of Senna produced in India is exported to western countries. The crop can be grown both under rainfed and irrigated conditions. It is cultivated in Maharashtra, Gujarat, Rajasthan, Karnataka and Tamil Nadu. It was considered as a “cleansing” herb because of its cathartic effect. It is mainly used as a purgative. It has the smell of tea and has stimulant and irritating laxative properties as well as cooling and anti-bacterial properties. It contains several dianthrone glycosides, anthraquionone glycosides, mucilage and flavanoids. It is used to treat acute constipation and used after anal-rectal surgery as it ensures soft stools and easy bowel movements. In addition, the leaves were sometimes made into a paste, and applied to various skin diseases. There is a general practice of drying the harvested leaves by spreading them on the floor, which results in contamination and affects quality. The appearance and leaf quality deteriorate due to the heat developed inside the thick layer while drying.

Improper and delayed drying changes the colour to black, which results in lower price in the market.(THE HINDU, dated 31.8.2006) Hence drying the crop in a mechanical dryer could alleviate the problem to a lesser extent thereby improving the quality for export market.

Materials & Methods

Raw Material

Freshly harvested senna leaves of the variety KKM-1 were used for conducting drying studies. The harvested leaves were obtained from farmer’s field.

Forced Flow Dryer

The dryer consists of a drying chamber, plenum chamber, heating chamber and a blower driven by 2HP motor. Loading and unloading of the material is done through the door provided at the drying chamber. An inspection door is provided at the front of the dryer. The ambient air entering through the blower gets heated up in the heating chamber having 6 kW electric heaters and enters into the plenum chamber. From the plenum chamber the hot enters into the drying chamber where the product is kept for drying. The hot air after absorbing moisture from the product is discharged into the atmosphere through the exhaust provided above the drying chamber. The overall dimension of the dryer was 900x900x16500 mm. (Fig. 1)

|

Figure 1: Forced flow type dryer. Click here to View figure |

Drying Studies

In one set of experiment 5 kg of harvested senna leaves were dried in the dryer at 40° C and in another trial 5 kg of the same was dried at 45°C. Senna leaves were also dried under shade (32±2ºC) for comparison. The initial moisture content of the leaves before drying was estimated by hot air oven method of drying. Weight of the samples were recorded at intermittent intervals during drying and the final moisture content of the sample was estimated based on the final weight achieved at the end of drying. Sennoside concentrate, an important parameter which decides the quality of the sample was estimated analytically.

Statistical Analysis

The experimental data was analyzed as per the procedure of one way/ two way classified ANOVA using computer software package“AgRes”

Results and Discussion

Drying Characteristics of Senna Leaves

Drying studies on senna leaves were conducted at 40 & 45°C temperatures in the forced flow type dryer. The initial moisture content of the leaves was estimated to be 186 % (d.b) and the leaves were dried to a final moisture content of about 5% (d.b). It could be seen from Fig. 2 , it took 2.5 hours to dry senna leaves at 45°C whereas for the same lot at 40°C the drying time was about 4 hours. For the same lot for shade drying of the leaves it took about 5 days for drying to a final moisture content of 5.9% (d.b) (Fig 3.)

|

Figure 2: Drying behaviour of Senna leaves by mechanical drying. Click here to View figure |

|

Figure 3: Drying behaviour of senna leaves by shade drying. Click here to View figure |

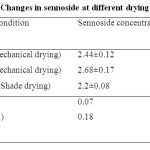

Effect of Drying on the Quality of Dried Senna

The quality of the dried senna leaves were evaluated in terms of its sennoside concentrate (Table 1) Statistical analysis revealed that there was significant difference in the sennoside concentrate at different drying condition. It could be seen that senna dried at 45°C (Fig.4) showed higher yields (2.69%) in terms of its sennoside concentrate whereas at 40°C it was 2.44 %. However shade dried sample had a low sennoside content of 2.2%. This may be due to the fact that during shade drying, since the sample is spread in layers, heat is formed inside the layers during slow drying which in turn affects the quality of the end product. Improper and delayed drying changes the leaf colour to black, which results in a lower price in the market (Prabhu, 2006)

|

Table 1: Changes in sennoside at different drying condition. Click here to View table |

|

Figure 4: Senna leaves dried at 45ºC. Click here to View figure |

References

- Anonymous, Senna, A dry land crop. 2007. Hand book on Medicinal and Aromatic Plants, Third Edition, Agro India, Bangalore.

- Kader Mohideen, M., Arumugam Shakila and Anburani, A. Production technology of medicinal and aromatic crops, Annamalai University, Chidambaram, 2006.

- Prabu, M.J. Senna variety ideal for rainfed farming in southern districts. THE HINDU dated 31.8.2006.