Introduction

Candy is a sweet food product made up of impregnating fruits or vegetables with syrup.1 Candy has witnessed a dynamic evolution marked by experimentation with various ingredients and techniques to enhance its attributes. From the early days of incorporating fruits or vegetables with syrups to the modern utilization of medicinal plants and herbs, the journey of candy formulation has been characterized by a relentless pursuit of excellence. This evolution reflects a multifaceted approach encompassing factors such as flavor, texture, stability, and, increasingly, health considerations.2 The addition of some medicinal plants and herbs could improve its antioxidant and antibacterial properties even some phytochemical characteristics which can make this a treating remedy for several health complications.3 Over the decades of the industrial era, several formulations have been experimented with to improve their stability, quality, texture, flavour, and pharmaceutical properties.4

Candy preparation has evolved significantly over time, with various reports available documenting the transition from early to modern methods.5,6,7,8,9 Different quantities of sweet syrup, such as honey and sugar syrup, were used for candy preparation with carrot and sliced citron (Citrus medica) peel, respectively.10 These formulations improved the flavours and storing capacity of the product up to a significant level.10 Likewise, in the pharmacological development of candy, the substitution of sugar with Stevia rebaudiana is applicable for reducing calories from candy up to 60%.1 Using of guava (Psidium guajava) as a flavoring agent is another formulation which improves colour and consistency as pinkish candy, in which potassium metabisulphite and sodium bisulfite could be applied as disinfectant, antioxidant, and preservative.10 Antioxidants may also be increased by using chokeberry extract which competes with synthetic dye as a colouring and flavouring agent.11 In addition, candies of beetroot and ginger have shown significant antioxidant activity.3 The other formulations of beetroot with steam-blanching showed better stability. Blanching has also been formulated as preparation of candy of unripe mango along with a mixture at 40oC. Brix sugar syrup was competing with other formulations.12,13 An implementation of glass transition temperature with calcium maltobionate which demonstrates an improved hardness level of candy, could be a competitive formulation for candy preparation.14 Nowadays, to facilitate children’s health compliance and cost-effective pharmaceutical formulations, the incorporation of metoclopramide hydrochloride and pomegranate juice is applied to make the candy soften.15 Demonstration of the various chemical formulations brings natural oils and extracts in competition with candy industries for better nutritional values.16 Enforcement of value-added products such as various peel waste management inspires candy preparation as beneficial applications.17 Tea extract could be chosen for candy preparation and agar and pectin have also been proven as a good alternative to gelatin.17 Innovations through grape, carob molasses and mulberry have also been examined to replace sugar syrup resulting in acceptable scores.18

Having reviewed the gradual development of candies, it is being observed that nowadays there is still a need to seek a better formulation of candy as per the current competitions of the confectionery industry. Therefore, seeking new formulations of candy beyond the above literatures some medicinal herbal plants could also be used such as cinnamon (Cinnamomum verum) a tropical herb reported as anti-inflammatory, antioxidant, antimicrobial, anti-diabetic, lipid-lowering, cardiovascular-disease-lowering compound and anticancer;19 Cardamom has been found as a flavoring agent in food preparations, confectioneries and cosmetics;20 Tinospora cordifolia (Giloy) which has tremendous medicinal property of anti-diabetic, anti-allergic, anti-inflammatory, antioxidant, antimalarial, antiepileptic, hepato-protective, antineoplastic activities and immuno-modulatory21 Foeniculum vulgare (Fennel) which has been reported as hepatoprotective, antioxidant, hypotensive, anti-inflammatory, bronchodilatory, galactagogue, estrogenic, diuretic, emmenagogue, antithrombotic, lithontriptic, gastroprotective, and antimutagenic activities.22 The exploration of candy formulations has evolved, driven by the continuous quest for innovation and effectiveness within the confectionery industry. Impregnation of more herbal plants could defiantly demand new formulation of candy with respect of texture, flavor and hardness therefore, with the inspirations of above studies, the present work has been designed to seek better effective and innovative formulation for candy preparation in which, hypothetically beetroot could be used into powder and form of juice with extracts of different herbal plants. The present study delves into integrating medicinal plants into candy formulations, aiming to redefine traditional approaches and elevate the nutritional and sensory profiles of these sweet treats.

Materials and Methods

The experimentation in the present study was conducted using a selection of high-quality herbal plants. Procedures involved in processing and grinding for extractions, as well as the steps for making herbal-based jelly candy i.e. soft-boiled candy without sugar (hereafter we mentioned it as candy only) and its subsequent storage, were carefully outlined. Two distinct formulations were employed in the preparation of the candy: one utilizing extracted juice and the other utilizing biomass of beetroot. Subsequently, the quality parameters including moisture content, total solid content, reducing sugar, and total sugar were assessed.

Sample Collection and Preparation

Fresh and mature beetroots (Beta vulgaris), cinnamon, cloves, jaggery, stevia, cardamom, giloy, fennel, and ginger were obtained from the local market. In this procedure, the juice and powder were extracted from the beetroot initially, which were subsequently utilized as distinct components for candy preparation. Following this, beetroot powder (BP) was combined with stevia to create first formulation known as BPS. This BPS formulation was then divided into 10 sub-formulations, with five stored at room temperature and the remaining five in the refrigerator. All these formulations were designated with specific codes: BPSRoCi (Cinnamon oil at room temperature), BPSRoCa (Cardamom oil at room temperature), BPSRoCl (Cloves oil at room temperature), BPSRoGi (Ginger oil at room temperature), BPSRoFe (Fennel oil at room temperature), BPSReCI (Cinnamon oil in the refrigerator), BPSReCa (Cardamom oil in the refrigerator), BPSReCl (Cloves oil in the refrigerator), BPSReGi (Ginger oil in the refrigerator), and BPSReFe (Fennel oil in the refrigerator). In contrast, beetroot juice (BJ) was mixed with jaggery to form a second formulation known as BJJ, which was further divided into 10 sub-formulations. Five were stored at room temperature, and the remaining five were kept in the refrigerator. Consequently, these formulations were encoded as BJJRoCi (Cinnamon oil at room temperature), BJJRoCa (Cardamom oil at room temperature), BJJRoCl (Cloves oil at room temperature), BJJRoGi (Ginger oil at room temperature), BJJRoFe (Fennel oil at room temperature), BJJReCi (Cinnamon oil in the refrigerator), BJJReCa (Cardamom oil in the refrigerator), BJJReCl (Cloves oil in the refrigerator), BJJReGi (Ginger oil in the refrigerator), and BJJReFe (Fennel oil in the refrigerator).

Processing of Formulations

This step was achieved using a well-designed stranded method adopted from a previously established approach.23 Whereby initial steps involved in the preparation of the beetroots included washing, peeling, and removing any inedible portions. Subsequently, the beetroots were cut into pieces measuring 2-3 cm and then ground until they reached a slurry consistency. The slurry was extracted using sterile muslin cloth. After the juice was extracted, the remaining biomass was considered as powder and utilized for a secondary preparation. The extracted juice was carefully transferred to an airtight jar and stored in the refrigerator for future use. This beetroot juice served as the base for candy formation, being combined with jaggery as a sweetening agent, along with various herbs such as dalchini, cloves, cinnamon, cardamom, giloy, fennel, and ginger for flavour enhancement.

|

Figure 1: Designing of the experiment for candy preparation. |

Processing for Candy Preparation

The preparation of candy using beetroot was carried out with two distinct formulations as shown in Fig. 1. Firstly by using beetroot powder and second by utilizing beetroot juice. The former was performed with stevia. In which the extracted biomass was dehydrated until dried followed by grinding for making powder form. Simultaneously, 1 g of dried stevia powder was dissolved into 1 L of distilled water (DW) separately and beetroot powder was then dissolved gently.

Additionally, various herbs including cinnamon, cardamom, giloy, cloves, fennel, and ginger extracts were individually dissolved to enhance the flavour profile. Subsequently, beetroot juice was combined with a jaggery solution (500 g per litre of water) and mixed thoroughly. To further enhance the flavour, separate 2 ml solutions of cinnamon, cardamom, giloy, cloves, fennel, and ginger were added. The mixtures were then heated to a temperature of 150ºC. Finally, both preparations were promptly poured into candy molds or trays with a capacity of 3 g each.

Storage and Sampling of Candies

Jaggery and stevia candies were stored in two different conditions. Each sample was stored at both refrigerator temperature (4ºC) and room temperature (25-27ºC) under industrial polythene packing for 2 months. Samples were then taken at 0, 30 and 60 days after storage and analyzed different parameters as described below.

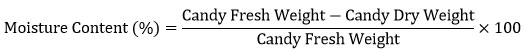

Moisture Content

The moisture contents (MC) of candies were determined by measuring fresh weight which was based on a method given by the Hampton.24 Three replicates of each candy preparation were taken, and the fresh weight was determined using a calibrated balance with 0.1 mg accuracy. Following fresh weight determination, the candies were kept for drying at 96oC in the hot air oven for 48 h and then their dry weight was taken. The candy MC was expressed in percentage (%) by following the formula:

Solid Content

To determine the total solid (TS) content, the initial and dried weight of each candy sample was recorded before and after drying the samples at 96oC in the hot air oven for 48 h.25 The basic principle of this technique is that water has a lower boiling point than the other major components within foods, e.g., lipids, proteins, carbohydrates, and minerals. The total solids content is a measure of the amount of material remaining after all the water has been evaporated. The candy TS content was expressed in percentage (%) by following the formula:

Reducing Sugar

The determination of reducing sugar (RS) content in both Jaggery and Stevia candies was conducted by following a well-designed method with slight modifications.25,26 Upon candy preparation, 2 grams of each candy sample were homogenized in distilled water and subsequently centrifuged. The supernatant was then collected and diluted up to 5 times with distilled water for total sugar determination. In this process, 5 ml of concentrated HCl was added to 50 ml of each candy sample. The mixture was heated for approximately 10 minutes in a water bath, followed by the addition of 5 ml of concentrated NaOH to neutralize the solution. The solution was further diluted five times with 0.1 N NaOH solutions. In a separate conical flask, 5 ml of Fehling-A solution and 5 ml of Fehling-B solution were combined and heated for an additional 1-3 minutes. This solution was titrated against the sample solution until the appearance of yellow or red precipitation, with methylene blue used as an indicator. The endpoint for each sample was recorded and the reducing sugar content was calculated using the formula provided below and expressed as a percentage (%).

Total Sugar

The total sugar content in the candy samples was determined by following a stranded method with slight modifications.27 Two grams of each candy sample were homogenized in DW and then centrifuged at 4000 rpm for 20 minutes. The supernatant was collected and diluted up to 5 times with DW for total sugar determination. One millilitre of each sample was mixed with 1 ml of a 5% aqueous solution of phenol and 5 ml of concentrated sulfuric acid in a test tube. The test tube was then placed in a 100°C water bath for 5 minutes and vortexed for 30 seconds to aid in colour development. The absorbance of the coloured samples was measured using a UV-visible spectrophotometer at 490 nm. The total sugar content was expressed as a percentage (%).

Data Analysis

In this study, all experiments were conducted in triplicate and repeated at least three times. All the data presented are the average of triplicates with standard deviation (SD). These triplicate values were then utilized to calculate standard deviations, and subsequently, the differences between variances were analyzed using ANOVA (Analysis of Variance). This statistical method enabled the assessment of variability among the variables.

Results

The current study was structured around the impregnation of essential oils from herbal medicinal plants, utilized as flavouring agents. These formulations were systematically modified and stored for up to 60 days. A total of 20 different formulations were applied, based on varying flavouring agents, to assess moisture content, solid content, reducing sugar, and total sugar levels sequentially.

Moisture Contents at Day 30th

The percentage of moisture content up to 30 days was estimated among various 20 formulations prepared separately by beetroot powder and juice with a duplet storage system, showing values between 15.0 to 18.9% demonstrated in Table 01. The room-dried formulation of cinnamon oil was found up to 16.4±1.75% representing 2.3 % of the reduced level of moisture contents. Likewise, cardamom oil was recorded up to 2.4 % followed by cloves oil (2.9%), ginger oil (4.1%) and fennel oil (3.4%). Comparisons with the same formulation stored in the refrigerator showed significant differences in moisture contents compared to room temperature, exhibiting values ranging from 17.6 to 18.9 %. Formulations of cinnamon oil, cardamom oil, cloves oil, ginger oil and fennel oil were recorded as 1.1%, 0.7%, 2.1%, 0.9% and 1% respectively. Comparative analysis of all the formulations concerning storage, the consequence is manifesting the formulation with room temperature is much better than the refrigerator. Similar parameters under the normal room temperature were examined with beetroot juice and jaggery with similar flavours indicating the reduction of moisture contents as 1.3%, 2.4%, 2.3%, 0.9% and 1% for cinnamon oil, cardamom oil, cloves oil, ginger oil, and fennel oil respectively. Whereas the reduction of moisture contents for formulations of refrigerators was recorded as 0.9%, 0.9%, 2.2%, 0.9% and 0.5 % for the same. Consequently, no significant differences have been observed in the reduction of moisture contents between the formulations of beetroot powder and juice. However, the formulations prepared by ginger were found better for candy preparation than other formulations.

Moisture Contents at Day 60th

The reduction of moisture contents was again estimated at day 60 from all of the 20 formulations which were based on beetroot powder and juice with stevia and jaggery by both types of storage system where the first is room temperature and the second is refrigerator (Table 02). Where the former gave the values of 5.2%, 5.5%, 5.1%, 7.3% and 6.4% and later were recorded as 2.0%, 3.3%, 3.7%, 2.5% and 2.1%. Alternatively, the juice with jaggery with storage at room temperature was found as 3.9%, 4.6%, 4.5%, 4.5% and 3.6%. Whereas the formulation under refrigerator temperature was found as 1.9%, 1.8%, 2.6%, 1.9% and 2.3% respectively. Here the formulation with ginger at room temperature has been found better for candy.

Solid Contents at Day 30th

The inversely proportional values with Solid Contents in the context of moisture for better candy formulation were observed up to day 30th shown in Table 01. In which the values of Cinnamon oil, Cardamom oil, Cloves oil, Ginger oil, and Fennel oil were recorded as 4.1%, 2.1%, 3.6%, 7.0% and 4.6% concerning the formulations of powder and stevia applied with room temperature. Whereas the slightly altered values have been recorded for formulation applied under refrigerators as 3.1%, 0.1%, 2.1%, 8.4% and 2.4% for cinnamon oil, cardamom oil, cloves oil, ginger oil, and fennel oil respectively. Simultaneously, the formulation of Juice and jaggery was also compared in which 3.1%, 1.2%, 1.9%, 6.4% and 3.1% were found for storage of room temperature the formulations of Cinnamon oil, Cardamom oil, Cloves oil, Ginger oil, and Fennel oil respectively. The result of the refrigerator indicates 1.2%, 3.1%, 0.2%, 7.1% and 0.6% for the same formulation of flavors. The Consequence of solid contents is again showing better values with ginger formulation. Whereas the values of solid content in room temperature were better than the refrigerator.

Solid Contents at Day 60th

The reduction of moisture contents could be an indication of solid content increasing which were estimated within 60 days from all 20 formulations which were based on storage at different conditions i.e. first was Beetroot powder and stevia at room temperature, second was Beetroot powder and stevia in the refrigerator, third was beetroot juice and jaggery with room temp and forth were beetroot juice and jaggery in refrigerator resulting these were recorded as 1. 9.8%, 8.6%, 9.3%, 16.3% and 13.6%. 2. 12.0%, 9.0%, 10.0%, 14.0% and 14.0%. 3.4.3%, 3.18%, 9.11%, 18.0% and 5.95%. 4.11.2%, 7.2%, 10.2%, 16.2% and 10.2% (Table 02).

Table 1: Comparison between values of two formulations for candy preparation from beetroot powder and juice within 30 days.

|

Sample Code |

Moisture content |

Solid content |

Reducing sugar |

Total sugar |

||||

|

Day 00 |

Day 30 |

Day 00 |

Day 30 |

Day 00 |

Day 30 |

Day 00 |

Day 30 |

|

|

BPSRoCi |

18.7± |

16.4± |

81.2± |

85.3± |

30.1± |

35.9± |

71.1± |

78.2± |

|

BPSRoCa |

19.2± |

16.8± |

82.2± |

84.3± |

30.5± |

36.8± |

71.9± |

79.2± |

|

BPSRoCl |

19.9± |

17.0± |

80.2± |

83.8± |

30.1± |

35.3± |

72.2± |

78.9± |

|

BPSRoGi |

19.1± |

15.0± |

79.2± |

86.2± |

29.3± |

36.2± |

72.0± |

83.0± |

|

BPSRoFe |

18.9± |

15.5± |

81.2± |

85.8± |

29.9± |

35.4± |

72.6± |

79.3± |

|

BPSReCi |

18.7± |

17.6± |

81.2± |

84.3± |

30.2± |

35.5± |

73.1± |

78.4± |

|

BPSReCa |

19.2± |

18.5± |

82.2± |

82.1± |

30.5± |

34.5± |

72.2± |

78.9± |

|

BPSReCl |

19.9± |

17.8± |

80.2± |

82.3± |

29.1± |

33.4± |

71.2± |

79.3± |

|

BPSReGi |

19.1± |

18.4± |

79.2± |

87.6± |

28.4± |

32.4± |

72.8± |

79.9± |

|

BPSReFe |

18.9± |

18.9± |

81.2± |

83.6± |

29.0± |

35.2± |

72.1± |

78.8± |

|

BJJRoCi |

18.7± |

17.4± |

81.2± |

84.3± |

30.2± |

34.7± |

73.1± |

78.3± |

|

BJJRoCa |

19.2± |

16.8± |

82.2± |

83.4± |

29.5± |

33.9± |

72.9± |

78.9± |

|

BJJRoCl |

19.9± |

17.6± |

80.2± |

82.1± |

28.9± |

34.9± |

73.2± |

79.2± |

|

BJJRoGi |

19.1± |

18.2± |

79.2± |

85.6± |

29.3± |

35.1± |

72.6± |

77.9± |

|

BJJRoFe |

18.9± |

17.9± |

81.2± |

84.3± |

29.9± |

34.9± |

72.6± |

77.9± |

|

BJJReCi |

18.7± |

17.8± |

81.2± |

82.4± |

30.2± |

30.9± |

73.1± |

76.9± |

|

BJJReCa |

19.2± |

18.3± |

82.2± |

79.1± |

29.5± |

32.4± |

72.9± |

77.3± |

|

BJJReCl |

19.9± |

17.7± |

80.2± |

80.4± |

28.9± |

31.8± |

73.2± |

77.5± |

|

BJJReGi |

19.1± |

18.2± |

79.2± |

86.3± |

29.3± |

32.3± |

72.8± |

77.2± |

|

BJJReFe |

18.9± |

18.4± |

81.2± |

81.8± |

29.9± |

32.6± |

72.6± |

76.7± |

Reducing sugar at Day 30th

The determination of reducing sugar up to day 30 among these formulations was estimated by comparing the values of day 00. Whereby, the higher results were recorded for the formulations of room temperature with the same flavouring agents as 5.8%, 6.3%, 5.2%, 6.9% and 5.5%. Whereas the values of the reducing sugar under the refrigerator were recorded as 5.3%, 4.0%, 4.3%, 4.0% and 6.1%. The result of the second formulation with beetroot juice and jaggery was again showing slightly different results in formulations of room temperature, which were 4.5%, 4.4%, 6.0%, 5.8% and 5.0% for the same flavouring agents. Similarly, 0.7%, 2.9%, 2.9%, 3.0% and 2.7% were recorded for refrigerator formulations (Table 01).

Reducing sugar at Day 60th

The estimations of reducing sugar up to 60 days were shown increasing values from all formulations of beetroot powder and stevia which were 13.0%, 11.6%, 12.2%, 11.9% and 11.6%. In contrast, the formulations with refrigerators were observed 8.8%, 10.7%, 9.0%, 10.0% and 9.9% from all the formulations (Table 02). The values of reducing sugar with beetroot juice and jaggery at room temperature were found as 11.2%, 10.0%, 10.2%, 11.8% and 10.2%. However, reducing sugar was found at cold storage as follows 6.6%, 7.9%, 8.7%, 8.8% and 6.8% respectively.

Table 2: Comparison of two formulations for candy preparation from Beetroot powder and juice within 60 days.

|

Sample Code |

Moisture Content |

Solid Content |

Reducing Sugar |

Total Sugar |

||||

|

Day 00 |

Day 60 |

Day 00 |

Day 60 |

Day 00 |

Day 60 |

Day 00 |

Day 60 |

|

|

BPSRoCi |

18.7± |

13.5± |

81.2± |

91.0± |

30.2± |

44.7± |

73.1± |

86.1± |

|

BPSRoCa |

19.2± |

13.7± |

82.2± |

90.8± |

29.5± |

45.4± |

72.9± |

84.5± |

|

BPSRoCl |

19.9± |

14.8± |

80.2± |

89.5± |

28.9± |

46.2± |

73.2± |

85.4± |

|

BPSRoGi |

19.1± |

11.8± |

79.2± |

95.5± |

29.3± |

45.8± |

72.8± |

84.7± |

|

BPSRoFe |

18.9± |

12.5± |

81.2± |

94.8± |

29.9± |

44.9± |

72.6± |

84.2± |

|

BPSReCI |

18.7± |

16.7± |

81.2± |

93.2± |

30.2± |

40.9± |

73.1± |

81.9± |

|

BPSReCa |

19.2± |

15.9± |

82.2± |

91.2± |

29.5± |

41.3± |

72.9± |

83.6± |

|

BPSReCl |

19.9± |

16.2± |

80.2± |

90.2± |

28.9± |

41.2± |

73.2± |

82.2± |

|

BPSReGi |

19.1± |

16.6± |

79.2± |

97.2± |

29.3± |

40.8± |

72.8± |

82.8± |

|

BPSReFe |

18.9± |

16.8± |

81.2± |

95.2± |

29.9± |

39.8± |

72.6± |

82.6± |

|

BJJRoCi |

18.7± |

14.8± |

81.2± |

85.50± |

30.2± |

44.8± |

73.1± |

84.3± |

|

BJJRoCa |

19.2± |

14.6± |

82.2± |

85.38± |

29.5± |

45.2± |

72.9± |

82.9± |

|

BJJRoCl |

19.9± |

15.4± |

80.2± |

86.25± |

28.9± |

46.3± |

73.2± |

83.4± |

|

BJJRoGi |

19.1± |

14.6± |

79.2± |

88.31± |

29.3± |

44.4± |

72.8± |

84.6± |

|

BJJRoFe |

18.9± |

15.3± |

81.2± |

87.15± |

29.9± |

44.3± |

72.6± |

82.8± |

|

BJJReCi |

18.7± |

16.8± |

81.2± |

92.4± |

30.2± |

36.8± |

73.1± |

81.4± |

|

BJJReCa |

19.2± |

17.4± |

82.2± |

89.4± |

29.5± |

38.0± |

72.9± |

80.8± |

|

BJJReCl |

19.9± |

17.3± |

80.2± |

90.4± |

28.9± |

37.6± |

73.2± |

83.6± |

|

BJJReGi |

19.1± |

17.2± |

79.2± |

95.4± |

29.3± |

38.1± |

72.8± |

82.4± |

|

BJJReFe |

18.9± |

16.6± |

81.2± |

91.4± |

29.9± |

36.7± |

72.6± |

80.3± |

Total sugar at Day 30th

The sugar level with free radicals and complex form was calculated by comparison with the values of day 00 with Day 30th where positive values were recorded for the formulations of beetroot powder and stevia with all the flavouring agents like 7.1%, 7.3%, 6.7%, 11.9% and 6.7%. The same formulations with refrigerators were recorded as 5.6%, 6.7%, 8.1%, 7.1% and 6.7%. Comparison with the formulations of beetroot juice and the values were found as 5.2%, 6.0%, 6.0%, 6.0% and 5.3%. Whereas the total sugar of formulations under refrigerators was estimated as 3.8%, 4.4%, 4.3%, 4.4% and 4.1% (Table 01). Consequently, ginger with storage at room temperature has again been found better among candy formulations.

Total Sugar at Day 60th

The increased values of total sugar were recorded from beetroot powder with stevia at room temp as 14.5%, 15.9%, 17.3%, 16.5% and 15.0%. The formulation of refrigerators was recorded as 10.7%, 11.8%, 12.3%, 11.5% and 10.0%. On the other side the increased values of total sugar from beetroot juice and jaggery with room temp were recorded as 14.6%, 15.7%, 17.4%, 14.4% and 14.4% and formulations of refrigerator were found as 8.3%, 8.5%, 10.4%, 9.6% and 7.7% (Table 02).

|

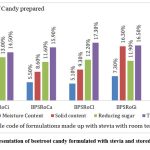

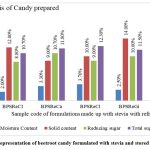

Figure 2: Quality representation of beetroot candy formulated with stevia and stored at room temperature. |

|

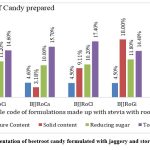

Figure 3: Quality representation of beetroot candy formulated with stevia and stored in the refrigerator. |

|

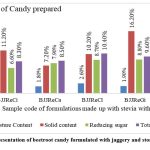

Figure 4: Quality representation of beetroot candy formulated with jaggery and stored at room temperature. |

|

Figure 5: Quality representation of beetroot candy formulated with jaggery and stored in the refrigerator. |

Discussion

The present hypothesis narrates about the formulations prepared from beetroot whereby, the data from day 00, 30 and 60 were arranged and analyzed by analysis of variance (ANOVA). The report of all mean values between variance has been found significant (P<0.05). In addition, the F value (58.96) was too high than the critical value (2.07) indicating the rejection of the hypothesis.

The scrutiny of new innovative and cost-effective formulations is continuously being searched by many confectionery industries. Hence the present work has been structured with experimentation of five different medicinal plants as flavoring agents. Ginger (BPSRoGi, BPSReGi, BJJRoGi, and BJJReGi) has been recorded as the best formulation with 7.0% increased values of solid content and 4.10% reduced moisture content (Fig. 2, 3, 4 & 5). The values of reducing sugar and total sugar have been found to have increased up to 6.9% and 11.90% respectively. Ginger has been experimented with four different formulations wherein two were made up with a mixing of Beetroot powder and stevia (Fig. 2 & 3) and another two were prepared with a mixing of beetroot juice and jaggery (Fig. 4 & 5). All the formulations were shown with the highest values. Whereas the remaining formulations show lower values. The present result agrees with other experiment which is concerning storages where formulations with room temperature were also found better than storage of refrigerators.28,29 Similar findings with the present work state that gradual decreasing of moisture content was found better in all formulations controlled under room temperature than storage of refrigerator. In contrast, this experiment was performed with organoleptic properties only as reported in available reports.23,30 Evaluation of carrot candy containing honey with various ratios exposing the reducing values of moisture content up to 28.0±0.50 %, reducing sugars up to 30.5±0.10% and total sugars was recorded as 78.0±0.20% which is too higher value than present work4. Citron candy preparation with various concentrations of sugar and potassium meta-bisulphite is revealing that increasing sugar concentration may improve the quality of candy which is opposite from the present study.31 Comparison with guava formulations with different concentrations of potassium meta-bisulphite where the highest moisture content loss was recorded up to 54.8% and increases of total soluble solid were recorded as 81.52% which were too higher values from the present work.10 Beetroot (Beta vulgaris) which is highly rich in betalain, phenolics and other bioactive components3,9 was experimented with as a new optimized formulation of candy preparation which showed significant results. The outcome by experimentation of calcium lactobionate to increase the physical stability of candy achieved an anhydrous form of sugar candy up to 66.4oC followed by isomaltose up to 56.6oC, sugarless candy up to 44°C. This study gives significant formulation which is altered from the present work.14,31 Substitution of carmoisine dye with various concentrations of chokeberry extract indicating a highly antioxidant value the consequence of the study is completely altered, besides the study associated with storage, stability, flavour, texture, solid contents and reducing sugar is missing.7,11 In one study on candy storage using Aonla fruit, the candy was made with ginger, mentha oil, peppermint oil, and lemon oil. The ginger formulation showed slightly better results, which is consistent with the findings of the current study.15 Meanwhile, one mango candy formulation showed very high results were observed over the 10 days of storage. Wherein, the formulation of hot water blanching with honey syrup showed 77.62% of total sugar which varies highly from the present study (16.50%).13,32 Formulation of white tea extract with steviol glycosides, sorbitol, and agave syrup and agar and pectin were examined with 120 days of storage to find the new fashion of candy showing very high values of (79.8%) solid contents with significant antioxidant values and the consequences of the study are much higher than present.22,33,34 One recent work on gummy candy was done by the replacement of sugar syrup with extracts of grape, mulberry, and carob molasses in which molasses were revealed as higher brix values between 78–79% from the present work18,35 The comparison of the above study is an indication that the present work is showing average values of moisture, solid, and sugar contents but is significant for candy preparation successfully. Among all five flavouring agents ginger was found to be better than others.

Conclusion

The incorporation of medicinal plants into candy formulations has been steadily advancing, aiming to revolutionize the confectionery industry. Driven by this goal, the current study utilized around 20 unique formulations, integrating a mixture of 5 different medicinal plants as flavor enhancers, having medicinal values. These formulations were stored under two conditions: at normal room temperature and in a refrigerator. Among the various formulations tested, ginger exhibited superior qualities compared to others, demonstrating the highest reduction in moisture content levels and increases in solid, reducing sugar, and total sugar contents. The collective properties of this formulation establish it as the optimal choice for candy preparation. In conclusion, the utilization of ginger in beetroot candy formulations shows promising potential for enhancing both sensory and nutritional attributes. Looking ahead, further exploration into the synergistic effects of medicinal plant combinations and optimized storage conditions could pave the way for innovative advancements in confectionery products with improved health benefits.

Acknowledgement

We extend our sincere appreciation to the School of Life and Allied Sciences, ITM University, Raipur, Chhattisgarh and the Principal of Government Rani Durgawati College, Wadrafnagar, Balrampur, Chhattisgarh for their invaluable support and collaboration in conducting this study.

Funding Sources

The author(s) received no financial support for the research, authorship, and publication of this article.

Conflict of Interest

The authors do not have any conflict of interest.

Data Availability Statement

The manuscript incorporates all the dataset produced or examined throughout this research study.

Ethical Approval Statement

This research did not involve human participants, animal subjects, or any material that requires ethical approval.

Informed Consent Statement

This study did not involve human participants, and therefore, informed consent was not required.

Authors Contribution

All the conceptualization and experimental design were undertaken by BS and SVS. AC and BS conducted the field experiments and data collection, while SVS and BS finalized the analysis and interpretation of the data. The manuscript was prepared by DT, RT, SS, and SVS.

References

- Durrani A.M., Srivastava P.K., Verma S. Development and quality evaluation of honey-based carrot candy. J Food Sci Technol. 2011;48(4):502-505.

CrossRef - Dolas R.T., Gangurde S.A., Wagh V.A., Chavan P.V., Gulecha V.S. Formulation and in vitro evaluation of polyherbal candy based on Indian medicinal plants for the treatment of cough and their stability studies. Bull Environ Pharmacol Life Sci. 2023;12:155-159.

- Kumar V., Kushwaha R., Goyal A., Tanwar B., Kaur J. Process optimization for the preparation of antioxidant-rich ginger candy using beetroot pomace extract. Food Chem. 2018;245:168-177.

CrossRef - Aranda G.I., Tamayo D.O., Barbosa M.E., Segura C.M., Moguel O.Y., Betancur A.D. Development of a gummy candy reduced in calories by sugar substitution with Stevia rebaudiana B. Nutr Hosp. 2014;31(1):334-340.

- Genovese D.B., Lannes S.C. Innovative approaches in the production of confectionery products: From novel ingredients to processing technologies. Food Res Int. 2021;140:110052.

- Popović S., Smiljanić K., Đorđević V. Herbal extracts in the development of functional confectionery products: A review. Food Res Int. 2022;147:110468.

- Kumar P., Sharma P. Advancements in flavor enhancement techniques for confectionery products. Food Chem. 2022;375:131739.

- Navale S.C., Paranjape A.N. Natural sweeteners and their role in the development of confectionery products. Curr Opin Food Sci. 2023;48:100953.

- Zhang Y., Guo X., Guo Q. Advancements in the formulation and production of functional candies: Current trends and future prospects. Trends Food Sci Technol. 2023;124:102-114.

- Kumar H., Ranote P.S., Goraya R.K. Development and quality evaluation of guava candy. Int J Pure Appl Biosci. 2017;6(7):119-126.

CrossRef - Ghendov-Mosanu A., Cristea E., Sturza R., Niculaua M., Patras A. Synthetic dye’s substitution with chokeberry extract in jelly candies. J Food Sci Technol. 2020;57(12):4383-4394.

CrossRef - Dobhal A., Awasthi P. Formulation of beetroot candy using simple processing techniques and quality evaluation. J Pharmacogn Phytochem. 2014;4(8):913-916.

- Mahato A., Chakraborty I., Baidya B.K. Preparation and evaluation of fruit candy from unripe mango. Int J Chem Stud. 2020;8(1):2727-2731.

CrossRef - Kawai K., Uneyama I., Ratanasumawong S., Hagura Y., Fukami K. Effect of calcium maltobionate on the glass transition temperature of model and hand-made hard candies. J Appl Glycosci. 2019;66(3):89-96.

CrossRef - Karaiskou S.G., Kouskoura M.G., Markopoulou C.K. Modern pediatric formulations of soft candies in the form of a jelly: Determination of metoclopramide content and dissolution. Pharm Dev Technol. 2020;25(1):20-27.

CrossRef - Cheriaparambil R.S., Naikare S.M. A study on generation of fruit waste among selected fruit juice outlets in Pune city and development of candied orange peel. Food Agric Spectrum. 2021;2(1):186-191.

- Šeremet D., Mandura A., Cebin A.V., Martinić A., Galić K., Komes D. Challenges in confectionery industry: Development and storage stability of innovative white tea-based candies. J Food Sci. 2020;85(7):2060-2068.

CrossRef - Kurt A., Bursa K., Toker O.S. Gummy candies production with natural sugar source: Effect of molasses types and gelatin ratios. Food Sci Technol Int. 2022;28(2):118-127.

CrossRef - Rao P.V., Gan S.H. Cinnamon: A multifaceted medicinal plant. Evid Based Complement Alternat Med. 2014;2014:642942.

CrossRef - Rajathi A.A., Sundarraj A.A., Leslie S., Shree M.P. Processing and medicinal uses of cardamom and ginger: A review. J Pharm Sci Res. 2019;11(3):2117-2122.

- Verma D.K., Kumar P., El-Shazly M. Unmasking the many faces of Giloy (Tinospora cordifolia L.): A fresh look on its phytochemical and medicinal properties. Curr Pharm Des. 2021;27(22):2571-2581.

CrossRef - Rahimi R., Ardekani M.R.S. Medicinal properties of Foeniculum vulgare Mill. in traditional Iranian medicine and modern phytotherapy. Chin J Integr Med. 2013;19(1):73-79.

CrossRef - Wany A.B., Verma S., Gupta L.K., Singh V.N., Thakur R., Sharma S., Sharma S.V. Development of probiotic from “Bassi,” a Chhattisgarhi fermented food containing suitable antioxidant values. Agr Res J. 2021;1(3):500-505.

CrossRef - Hampton J.G. The ISTA perspective of seed vigor testing. J Seed Technol. 1993;17(2):105-109.

- Sahu B., Naithani S.C. Role of reactive oxygen species and antioxidative enzymes in the loss and re-establishment of desiccation tolerance in germinated pea seeds. South Afr J Bot. 2023;163:75-86.

CrossRef - Pithava V., Pandey A. Quality assessment of different brands of mango juice available in the Indian market for carbohydrates and acids (ascorbic acid) by conventional titration method. Int J Pharm Sci Res. 2018;9(11):4826-4831.

- Sewwandi S.L., Karunaratne H.K., Madushani J.A. Literature review on selected Ayurvedic formula in the management of wound healing. GSC Biol Pharm Sci. 2023;24(2):220-227.

CrossRef - Kaikadi M.A., Chavan U.D., Adsule R.N. Studies on preparation and shelf-life of ber candy. Beverage Food World. 2006;33:49-50.

- Pushpangadan P., Kaur J., Sharma J. Plantain or edible banana (Musa x paradisiaca var. sapientum): Some lesser-known folk uses in India. Ancient Sci Life. 1989;9(1):20-24.

- Das S., Raychaudhuri U., Falchi M. Beetroot and its health benefits. Crit Rev Food Sci Nutr. 2021;61(1):1-22.

- Shamrez B., Aftab S., Junaid M., Ahmed N., Ahmed S. Preparation and evaluation of candies from citron peel. J Environ Sci Toxicol Food Technol. 2013;4(7):21-24.

CrossRef - Arshad S., Rehman T., Saif S., Rajoka M.S.R., Ranjha M.M.A.N., Hassoun A., Cropotova J., Trif M., Younas A., Aadil R.M. Replacement of refined sugar by natural sweeteners: Focus on potential health benefits. 2022;8(9).

CrossRef - Sahu B., Sahu A.K., Thomas V., Naithani S.C. Reactive oxygen species, lipid peroxidation, protein oxidation, and antioxidative enzymes in dehydrating Karanj (Pongamia pinnata) seeds during storage. South Afr J Bot. 2017;112:383-390.

CrossRef - Jain A., Mehra R., Garhwal R., Rafiq S., Sharma S., Singh B., Kumar S., Kumar K., Kumar N., Kumar H. Manufacturing and characterization of whey and stevia-based popsicles enriched with concentrated beetroot juice. J Food Sci Technol. 2022;59(9):3591-3599.

CrossRef - Shaukat M.N., Nazir A., Fallico B. Ginger bioactives: A comprehensive review of health benefits and potential food applications. 2023;12(11):2015.

CrossRef