Introduction

Rice (Oryza sativa L.) is a vital cereal food crop for more than half of the world’s population. Among the cereals, rice is more nutritious of about 40 per cent of world population consumes as a major source of calorie. More than 90 per cent of the world’s rice is produced and consumed in Asia, where it is an integral part of culture and tradition. India is the second largest producer after China and has an area of over 43.95 m ha and production of 106.54 m t with productivity of 2424 kg/ha. The total area under rice in Karnataka is 1.29 m ha with an annual production of 3.6 m t and the productivity is 2630 kg /ha during 2014-15.1

Thungabhadra area is referred to as ‘Rice Bowl of Karnataka’, since nearly 65 per cent of total (3.63 lakh ha) area of paddy in Karnataka including the Thungabhadra Project (TBP) command area (Ballari, Koppal and Raichur districts). The Tungabhadra river sub-basin, the main area lies within the Krishna River Basin and largely within Karnataka. Rainfall for the sub-basin follows a monsoonal pattern and roughly reflects elevation, which ranges from 1,200 to 1500 m. Annual rainfall is from 300 cm in the south (Western Ghats) and less than 50 cm in the northeast. In TBP command area, paddy-paddy based cropping system is the predominant system. The term paddy residue with its connotations of something left over that nobody wants, gives a false impression of the value of the straw, stubbles and other vegetative parts of crops that remain after harvest, especially since many farmers burn them or otherwise dispose of them. These paddy residues are used as animal feed, for thatching of homes and as source of domestic and industrial fuel. A large portion of unused crop residues are burnt in the fields primarily to clear the left-over straw and stubbles after the harvest. Non availability of labour, high cost of residue removal from the field and increasing use of combine harvesters are main reasons behind burning of crop residues in the fields.3 The residues of paddy, wheat, cotton, maize, millet, sugarcane, jute, rapeseed-mustard and groundnut are typically burnt on-farm across different states of the country. The problem is more severe in the irrigated agriculture, particularly in the mechanized paddy-paddy based cropping system in south India. Burning of crop residues is economic loss in addition to cause’s environmental pollution, is hazardous to human health, produces greenhouse gases causing global warming and results in loss of plant nutrients like N, P, K and S. Therefore, appropriate management of crop residues assumes a great significance.2

In this context, paddy crop residues are of tremendous value to the farmers. However, a large portion of paddy residues is burnt on-farm primarily to clear the field for sowing/planting of the succeeding paddy crop. The on-farm burning practice of crop residues is intensifying in recent years due to shortage of human labour, high cost of removing the crop residues by conventional methods and use of combine for harvesting of crops.5 The paddy residues are typically burnt on-farm across different regions of the TBP area. The problem is more severe in the head and mid region of the command area, particularly in the mechanized paddy-paddy and the availability of short time between kharif paddy harvesting and sowing of rabi/summer paddy. Keeping in view the above issues, this investigation was undertaken with the objectives as to identify the different crop residue management practices and also determine the socio-economic factors influencing the different crop residue management practices in TBP command area.

Materials and Method

The study was carried out purposively in Tungabhadra Project (TBP) Command area of Karnataka during 2015-16. The stratified multistage random sampling technique was used for the selection of farmers from the TBP command areas. In the first stage, three districts of TBP area namely Koppal, Ballari, and Raichur were selected. In the second stage, the five taluks namely Gangavati, Siruguppa, Hospet, Sindhanur and Manvi were selected from the selected districts based on the location of command area. In the third stage, four villages from each taluka were selected based on density of livestock population i.e. two villages having highest and two having lowest livestock density depends on the data and information obtained from veterinary offices of the respective taluks. In fourth stage, five farmers from each village were selected for the study. Thus, the total sample size comprised of 100 farmers. The data were analyzed by using descriptive statistics and Multinomial logit regression model.

Multinomial “Logit” regression model

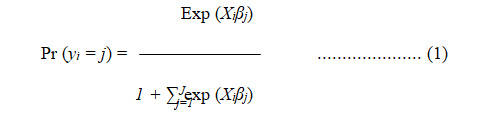

Multinomial logistic regression was used to predict categorical placement in or the probability of category membership on a dependent variable based on multiple independent variables. The independent variables can be either dichotomous (binary) or continuous (interval or ratio in scale). Multinomial logistic regression is a simple extension of binary logistic regression that allows for more than two categories of the dependent or outcome variable. Like binary logistic regression, multinomial logistic regression uses maximum likelihood estimation to evaluate the probability of categorical membership.

The multinomial logit regression model was used to express the probability of a farmer being in a particular category. The farmers were categorized into four groups based on the type of residue management practices followed. The practices include the removal of loose straw and burning of stubbles, burning of loose straw and stubble, removal of loose straw and incorporation of stubble and incorporation of loose straw and stubble.

The general form of the multinomial logit model is:

Where,

for the ith individual, yi is the observed outcome and Xi is a vector of explanatory variables. βj is the unknown parameters.

(j = 1, 2, 3, 4)

1= Removal of straw and burning of stubble

2= Burning of straw and stubble

3= Removal of straw and incorporation of stubble

4= Incorporation of straw and stubble

The explicit form of the functions is specified as follows:

Pij = β0 + β1 AGE +β2F_SIZE + β3AREA + β4F_EXPERIENCE + β5EDU + β6F_IMPL + β7ANIMALS+ β8 Gr_INC +β9TRAINING PROGRAMME.

Where as,

Β0= Intercept

β1 =Average age of sample farmers (-ve)

β2 = Average number of persons in a family (+ve)

β3= Average acre under the paddy (-ve)

β4= Average year experience in paddy cultivation (+ve)

β5= Number of years education (+ve)

β6 = Average number of tractor and other implements (-ve)

β7 = Average number livestock owned by sample farmers (+ve)

β8= Gross returns Rs. from the agriculture (+ve)

β9= Average number of agriculture training attended by sample of farmers (+ve)

Note: Figures in Parentheses indicate the expected sign

Results and Discussion

In TBP command area, the paddy straw was used as a major source for animal feed so it had high value so the farmers are not ready to lose the income from the paddy residue so the major farmers in the command area are collecting the paddy residue and burning only remaining stubbles. The combine harvesting technologies, which have become common in rice cultivation in India, leave behind large quantities of straw in the field for animal feed and open burning of residue.7 The farmers are collecting paddy residue because it has versatile by-products and also used in many ways as fodder for livestock and as a building material.

Paddy residue management practices

There were identified four methods of paddy residue management practices as removal of loose straw and burning of stubbles, burning of loose straw and stubbles, removal of straw and incorporation of stubbles and incorporation of loose straw and stubbles. Among the selected farmers about 48 per cent were practicing removal of loose straw and burning stubbles on an area of 42.25 per cent followed by removal of loose straw and incorporation stubbles (22.00 % farmers on 23.31 % area), burning of loose straw and stubbles (19.00 % farmers on 24.53 % area) and incorporation of loose straw and stubbles (11.00 % of farmers on 9.71% of area). Where in case of manual harvesting, removal of loose straw and burning stubbles was the leading practice by the 57.89 per cent of farmers with 54.12 per cent of area followed by burning of loose straw and stubbles (15.79 % farmers on 18.82 % area), removal of loose straw and incorporation stubbles (15.79 % farmers on 17.65 % area) and incorporation of loose straw and stubbles (10.53 % farmers on 9.41% area). Similarly, the mechanical/combine harvesting, removal of loose straw and burning stubbles method of residue management was the leading practices by 45.68 per cent of farmers on 41.29 per cent of area followed by removal of loose straw and incorporation stubbles (23.46 % farmers on 23.87 % area), burning of loose straw and stubbles (19.75 % farmers on 25.10 % area) and incorporation of loose straw and stubbles (11.11 % farmers on 9.74 % area) (Table 1).

Table 1: Paddy residue management practices performed in Tungabhadra area during 2015-16.

|

Sl. No. |

Practices |

Manual

|

Combine harvester

|

Total

|

|||

| No. of farmers |

Area (acre) |

No. of farmers |

Area (acre) |

No. of farmers |

Area (acre) |

||

|

1 |

RS & BS |

11.00 (57.89) |

92.00 (54.12) |

37.00 (45.68) |

704.00 (41.29) |

48.00 (48.00) |

796.00 (42.45) |

|

2 |

BS & S |

3.00 (15.79) |

32.00 (18.82) |

16.00 (19.75) |

428.00 (25.10) |

19.00 (19.00) |

460.00 (24.53) |

|

3 |

RS &IS |

3.00 (15.79) |

30.00 (17.65) |

19.00 (23.46) |

407.00 (23.87) |

22.00 (22.00) |

437.00 (23.31) |

|

4 |

IS & S |

2.00 (10.53) |

16.00 (9.41) |

9.00 (11.11) |

166.00 (9.74) |

11.00 (11.00) |

182.00 (9.71) |

|

|

Overall |

19.00 (100.00) |

170.00 (100.00) |

81.00 (100.00) |

1705.00 (100.00) |

100.00 (100.00) |

1875.00 (100.00) |

Note: Figures in the parentheses are percentages to the column sample total

RS & BS: Removal of loose straw and burning of stubbles

BS & S: Burning of loose straw and stubbles

RS &IS: Removal of loose straw and incorporation of stubbles

IS & S: Incorporation of loose straw and stubbles

Socioeconomic characteristics of selected farmers

Overall, an average age of respondents was 42 years. Among the different practices, the practice of incorporation of loose straw and stubbles of rice was followed by the farmers of the average age of 45 years, burning of loose straw and stubbles (44.49 years), removal of loose straw and burning stubbles (42.00 years) and removal of loose straw and incorporation stubbles (39.50 years). Overall, an average family size was 5.89, the practice of removal of loose straw and incorporation stubbles was used those who are having the family size of 6.23 followed by removal of loose straw and incorporation stubbles (5.87), incorporation of loose straw and stubbles (5.75) and burning of loose straw and stubbles (5.72). Overall, an average farming experience of family was 10.70 years, among the different practices, incorporation of loose straw and stubbles method was adopted by the family having the experience of 12.02 years followed by burning of loose straw and stubbles (10.80 years), removal of loose straw and burning stubbles (10.49 years) and removal of loose straw and incorporation stubbles (9.50 years). The average area under paddy was 7.45 acre in overall, area under the practice of burning of loose straw and stubbles was 8.39 acre followed by removal of loose straw and incorporation stubbles (8.32 acre), removal of loose straw and burning stubbles (6.94 acre) and incorporation of loose straw and stubbles (6.09 acre). An average family income of respondent farmer was of ₹ 90,558, whereas, the income of the respondent who adopted the practice of incorporation of loose straw and stubbles was of ₹ 92114 followed by removal of loose straw and burning stubbles (₹ 91703), removal of loose straw and incorporation stubbles (₹ 89554) and burning of loose straw and stubbles (₹ 88858)10 (Table 2).

Table 2: Socio-economic characteristics of selected farmers during 2015-16.

| Sl. No. |

Particulars |

RS & BS |

BS & S |

RS &IS |

IS & S |

Overall |

|

1 |

Age(Years) |

42.00 |

44.49 |

39.50 |

45.02 |

42.75 |

|

2 |

Family size(No.) |

6.23 |

5.72 |

5.87 |

5.75 |

5.89 |

|

3 |

Farming experience of family (years) |

10.49 |

10.80 |

9.50 |

12.02 |

10.70 |

|

4 |

Area under paddy (acre) |

6.94 |

8.39 |

8.38 |

6.09 |

7.45 |

|

5 |

Family income per year (₹) |

91704 |

88859 |

89554 |

92114 |

90558 |

RS & BS: Removal of loose straw and burning of stubbles

BS & S: Burning of loose straw and stubbles

RS &IS: Removal of loose straw and incorporation of stubbles

IS & S: Incorporation of loose straw and stubbles

Economics of paddy residue management practices

It was observed in table 3 that the total variable cost per acre was higher in case of incorporation of loose straw and stubbles (₹ 30030) residue management practice followed by removal of loose straw and burning stubbles (₹ 29606) and removal of loose straw and incorporation stubbles (₹ 29345), whereas, lowest was recorded in burning of loose straw and stubbles (₹ 26617). The total fixed cost per acre was ₹ 11816 in case of incorporation of loose straw and stubbles followed by removal of loose straw and incorporation stubbles and removal of loose straw and burning stubbles recorded the cost of ₹ 11816, 11810 and 11799 per acre, respectively. The lowest fixed cost of ₹ 11795 was observed in burning of loose straw and stubbles. In case of total cost per acre, the incorporation of loose straw and stubbles (₹ 41846) was recorded highest, whereas, burning of loose straw and stubbles (₹ 38411) recorded lowest. The removal of loose straw and burning stubbles and removal of loose straw and incorporation stubbles recorded the total cost of ₹ 41405 and 41156, respectively. The highest yield was recorded with the incorporation of loose straw and stubbles of 29.75q/acre followed by removal of loose straw and incorporation stubbles of 29.15q/acre and removal of loose straw and burning stubbles of 28.58q/acre, whereas, burning of straw and stubbles recorded lowest yield of 28.11q/acre. Return per rupee of spent was slightly higher in farmers practicing removal of loose straw and burning stubbles (1.30) followed by removal of loose straw and incorporation stubbles (1.27) method of paddy residue management compared to burning of loose straw and stubbles (1.23) and incorporation of loose straw and stubbles (1.20). In overall, the total variable cost per acre was of ₹ 26895.34, total fixed cost per acre of ₹ 11805.08, total cost per acre of ₹ 38700.42, yield of 28.86q/acre, returns per rupee of investment of 1.25.

Table 3: Cost and returns under different residue management practices during 2015-16 (₹/acre)

|

Sl. No.

|

Particulars

|

RS & BS |

BS & S |

RS &IS |

IS & S |

|

I |

Total Variable Cost (₹) |

29606 |

26617 |

29345 |

30030 |

|

Ii |

Total Fixed Cost (₹) |

11799 |

11795 |

11810 |

11816 |

|

Iii |

Total Cost (₹) |

41405 |

38411 |

41156 |

41846 |

|

Iv |

Main product (q) |

28.58 |

28.11 |

29.15 |

29.75 |

|

V |

By- product value (₹) |

5250 |

– |

3200 |

– |

|

Vi |

Gross Return (₹) |

53761 |

46743 |

52111 |

50201 |

|

Vii |

Net Return (₹) |

12356 |

8332 |

10955 |

8355 |

|

viii |

Returns per rupee of investment |

1.30 |

1.23 |

1.27 |

1.20 |

Note: RS & BS: Removal of loose straw and burning of stubbles

BS & S: Burning of loose straw and stubbles

RS &IS: Removal of loose straw and incorporation of stubbles

IS & S: Incorporation of loose straw and stubbles

Table 4: Coefficient of variance as influenced by socio-economic factors and crop residue management practices during 2015-16.

|

X’s |

Description |

RS & BS |

BS & S |

RS & IS |

IS & S |

| Intercept |

– |

-75.16 (3875.43) |

-101.88 (4463.05) |

-67.59 (3919.58) |

-106.03 (3945.64) |

| Age (Years) |

Average age of sample farmers |

-0.31 (0.34) |

-0.25 (0.35) |

-0.16 (0.35) |

-0.18 (0.35) |

| Family size (No.) |

Average number of persons in family |

-0.88 (172.21) |

-1.01 (172.21) |

-1.24 (172.21) |

-0.65 (172.21) |

| Area (acre) |

Average area under the paddy |

-0.88** (58.43) |

1.39 (58.43) |

1.21 (58.43) |

1.16 (58.43) |

| Farming experience(years) |

Average experience in paddy cultivation |

-2.33 (73.27) |

-2.31 (73.27) |

2.28** (73.27) |

2.09** (73.27) |

| Education (Years) |

Number of years education |

-7.68 (3023.86) |

-30.89** (3747.48) |

5.51 (3058.16) |

6.49 (3058.16) |

| Farm implements (No.) |

Number of tractor and other implements |

-7.52 (977.32) |

6.27 (977.32) |

16.77 (1221.19) |

19.71** (1307.90) |

| Number of animals (No.) |

Number buffalo, bullock, cow, sheep and goat in sample farmers |

0.46** (91.91) |

-0.55 (91.91) |

0.07** (91.91) |

-0.20 (91.91) |

| Gross income |

From the agriculture |

0.003 (0.00) |

0.003 (0.00) |

0.002 (0.00) |

0.003 (0.00) |

| Training programmes |

No. of agriculture training attended by sample of farmers |

-17.32 (711.20) |

-20.51 (711.20) |

18.50** (711.20) |

18.30** (711.20) |

RS & BS: Removal of straw and burning of stubble

BS & S: Burning of straw and stubble

RS &IS: Removal of straw and incorporation of stubble

IS & S: Incorporation of straw and stubble

X’s= Explanatory variables

Number of observation = 100.

Numbers in parentheses are S.E value

Pseudo R2 = 0.730 ** = Significant at 5% level of probability

Multinomial logit model

The socioeconomic factors influencing the different residue management practices were analysed by using multinomial logit model. The relationship among the different methods was recorded. The area under paddy cultivation is an important factor influencing various residue management practices and it has a significantly negative influence on the practice of removal of loose straw and burning of stubbles. Thus, as hypothesized, larger the farms, the lesser the possibility of removal and incorporation of residue. The number of animals has a significant influence on the removal of loose straw and burning of stubbles method of residue management. Whereas, in case of burning of loose straw and stubbles method, education has negative influence and it was statistically significant. With regard to the removal of loose straw and incorporation of stubbles method, farming experience, numbers of animals and training programmes had positive influence.9

Similar results were reported in south east Asia,4 farming experience, farm implements and training programmes had positive and significant influence on incorporation of loose straw and stubbles method of practicing. Another study also reported the similar results of the logit model showed that the farmers’ education, number of paddy straw compost trainings in which the farmer participated, lack of knowledge about technology, insufficient labour and difficulty in making rice straw compost had a significant impact on the farmer’s decision to use paddy straw compost.8

Conclusion

In TBP command area, 81 per cent of farmers harvesting paddy crop through the machine (i.e. combine harvesters). The majority of farmers are practicing removal of loose straw and burning of stubbles (42.45 %) in TBP command area. The major factors, which influence to the decision to burn paddy crop residue are the use of combine harvesters and scarcity of labour for collection of residue. The highest livestock possession was found in case of removal of loose straw and burning of stubbles method of paddy residue management. Around 10.09 per cent of the total costs on residue management were constituted by labour and machine for field preparation in case of removal of loose straw and burning of stubbles method.

In total more than 67 per cent of farmers were practicing partial and complete burning of paddy residue. Therefore, there is a need to introduce and subsidize farm equipments required for the incorporation of paddy residue in the soils. It was found that higher cost is required for collection of residues compared to burning, to overcome this, government should provide subsidize equipment/machines required for baling of paddy residue using reaper binder and transport it to fodder scarcity areas or thereby created fodder banks. In this connection, the Government could promote the reaper binder by subsidized price. Paddy residue burning causing many health problems for both human and animals during burning season, to reduce this problems, there is need of agricultural extension services for creating awareness and education regarding the climate and air pollution associated with the burning of paddy residue, as well as the long term benefits of residue incorporation in the soil.

Acknowledgements

It is very difficult to express one’s feelings in words but formality demands to do so the extent possible. I feel the inadequacy of diction in expressing my sincere heartfelt gratitude to Dr. Lokesh G. B. Assistant Professor, Department of Agricultural Economics, College of Agriculture, Raichur and the Chairman of my advisory committee. His level of guidance, lively encouragement, constructive criticism and generous assistance at every stage of my research work, is behind measure, in fact it was he who motivated me to work on this aspect and any credit goes to him, his keen observations in detecting errors and correcting manuscript which consumed his valuable time and efforts is far beyond the call of duty. His kind and understanding nature has been overwhelming and unforgettable throughout my life. I owe my heartfelt thanks and gratitude to the members of my Advisory Committee Dr. Suresh. S. Patil, Dean (Agri), College of Agriculture, Bheemarayanagudi, and Dr. H. Lokesh, Professor, Department of Agricultural Economics, Raichur,

I hereby declare that the material being presented by me in this manuscript is our original work, and does not contain or include material taken from other copyrighted sources. Wherever such material has been included, proper citation is included in reference section. The content of manuscript is not substantially the same as any that i have already published elsewhere. I have not submitted this manuscript for publication anywhere else. There is no funding source during research work. The article and this submission form identify all co‐authors who have substantially contributed in research and preparation of the manuscript. All authors have read and approved the manuscript as submitted to Department Of Agricultural Economics College Of Agriculture, Raichur University Of Agricultural Sciences, Raichur the and are prepared to take public responsibility for the work. The submitted manuscript is thoroughly proof read by me and in conformity with the instructions for authors of the journal.

References

- Anonymous. State wise area, production and yield of rice 2014-15. Directorate of Economics and Statistics, Ministry of Agriculture, Govt. of India. 2015, pp 151-152.

- Adam J. Alternatives to open-field burning on paddy farms. Agric. Food Policy Studies Institute, Malaysia, 2013; 18(2): 1-5.

- Badarinath K. V. S., KiranChand T. R., Prasad K V. Agriculture crop residue burning in the Indo-Gangetic Plains – A study using IRS-P6 AWiFS satellite data. Current Sci., 2006; 91(8): 2 5-32.

- Cheryll C. Launio, Constancio A. Asis, Rowena G. M., Evelyn F. J. Economic analysis of rice straw management alternatives and understanding farmers’ choices. Econ. Envt. Program for South East Asia. 2013; pp 13-18.

- Gupta P., Sahai S., Singh N., Dixit C., Singh D., Sharma C., Tiwari M., Gupta R., Garg, S. Residue burning in rice-wheat cropping system: causes and implications. Current Sci., 2004; 87(12): 1713-1717.

- Kanokkanjana K., Garivait S. Alternative rice straw management practices to reduce field open burning in Thailand. Int. J. Env. Sci. Dev., 2013; 4(2): 17-23.

- Prabhat K. G., Shivraj S., Nahar S., Dixit C. K., Singh D. P., Sharma C., Tiwari M. K., Raj K. G., Garg S. C. Residue burning in rice–wheat cropping system: Causes and implications. Current Sci., 2004; 87(12): 113-119.

- Poungchompu, S., Tsuneo, K. and Chantanop, S. Factors affecting farmers’ decisions on utilization of rice straw compost in Northeastern Thailand, J. Agric Rural Dev. in the Tropics and Subtropic. 2013; 114(1): 21-27.

- Ridhima Gupta. The economic causes of crop residue burning in Western Indo-Gangetic Plains. Econ. Envt. 2012; 81(12): 66-72.

- Roguel S. M., Malasa R. B., Tanzo I. R. Social impact assessment of rice hull-burning & stale-seedbed technique of IPM-CRSP. Philippine J. Crop Sci., 2004; 27(3): 53-58.