Introduction

India is one of the largest producers of spices in the world. Garlic (Allium sativum) is used as a spice throughout India. It is also important foreign exchange earner for India. It has high nutritive it is rich in proteins, phosphorous, potassium, calcium, magnesium and carbohydrates. Drying of garlic is very essential to remove excess moisture from the outer skin and neck to reduce storage rot and its shelf life also it’s easy to use in dried form. Drying of agricultural produce is the oldest and still the most practiced preservation method. Demand of dried products is increasing all over the world. Dried products serve as an alternative to fresh fruits and vegetables and requires less maintenance during storage1 also drying is an environmentally friendly and economically viable technique.2 In India drying of fruits and vegetables is generally done by open sun drying. The initial moisture content of the agricultural products is the main factor behind the post harvest losses and open sun drying is the oldest technique that preserve the products by reducing the moisture contents. The reduced moisture content of agricultural products not only slow down the deterioration, but also increases the safe storage period. The main drawback behind the open sun drying is that the products remain unprotected from the environmental conditions like rain, dust, dirt, and infestation by birds and animals. All these factors affect the quality of food and sometimes the quality is degraded to an extent that it becomes inedible. The loss in quality of dried products affect market value and consumer acceptance.3,4,5 The solution to all these problems is use of tunnel dryers based on solar energy. These kind of dryers uses only solar energy and does not require any other source of energy also temperature inside the dryer is more than the atmosphere. Therefore, solar tunnel dryer is an alternative for rural people to reduce the storage losses by drying their produce in a controlled and better environment. Also, the dried product is free from any dust particles and highly acceptable by consumers.5,6 Other advantages of solar tunnel dryers are substantial reduction of drying time and physical quality standards are maintained also solar tunnel dryers are easy to operate and maintain.7 This paper presents results of performance of the solar tunnel dryer for drying of garlic.

Material and Methods

The experiment was carried out under the meteorological conditions of Hisar (latitude of 10.39ºN; longitude of 77.03ºE) in India during the month of June from 10.00 a.m. to 16.00 a.m..

Solar Tunnel Dryer

A low cost Solar Tunnel Dryer of different capacity for drying of fruits & vegetables and other agro industrial products was developed at MPUAT, Udaipur. Realizing the importance and use for the upliftment of farmers similar dryer with a floor area of 10m × 3.75m was installed at Hisar to evaluate its performance in ambient conditions of Haryana. The solar tunnel dryer is framed using UV-stabilized polythene sheet of height 1.98 meter. The orientation of tunnel solar dryer is in the east – west direction to use maximum sunlight.

Instrumentation

Six thermometers were fixed at different locations inside the drier to measure the temperature as shown in figure 1. A solar intensity meter was used to measure the instantaneous solar radiation. A digital electronic balance was used to weigh the samples.

|

Figure 1: Position of various thermometers inside the STD. Click here to View figure |

Experimental Procedure

Garlic

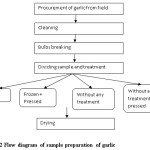

Freshly harvested 400 kg of garlic was purchased from the university farm of CCSHAU, Hisar during the month of June. The garlic was then cleaned manually and unwanted material like straw and dust were removed. Weight left after cleaning was 270 kg then the bulbs were broken into cloves using garlic bulb breaking machine, then the initial weight of the total sample was recorded and it was found 255 kg. The loose ‘papery shell” is removed by aspiration. The whole was divided into four parts. Two parts were frozen in deep freezer for two days and the remaining two parts were kept at room temperature after this one frozen part and one at normal temperature were pressed using the garlic pressing machine. Initial weight and initial moisture content of all the samples were recorded then the samples were used for drying at full load conditions in solar tunnel dryer. The whole process of sample preparation of garlic for drying is presented in the Figure 2 in the form of flow diagram.

|

Figure 2: Flow diagram of sample preparation of garlic. Click here to View figure |

The solar intensity, ambient and temperature inside solar tunnel dryer were measured every two hour interval till the end of drying. After attaining safe moisture the products were removed from the dryer. Fig3 (a) shows solar tunnel dryer at full load conditions and (b) garlic pressing machine.

|

Figure 3: solar tunnel dryer at full load conditions with garlic and garlic pressing machine. Click here to View figure |

Data Analysis

Determination of moisture content

To find out the initial moisture content about 12 g of samples were taken in a oven and the moisture content on wet basis ( wb ) was calculated using the Eq.(1). Initial (mi) and final mass (mf) at time (t) of samples were recorded using electronic balance and repeated after every 1 h interval till the end of drying on oven.

M (% wb) = (mi – mf)/ mi —— (1)

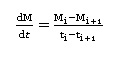

Determination of drying rate

Drying rate was calculated as weight of water removed per unit time by using the formula:

Where, dm/dt = Drying rate, percent moisture loss per hour, Mi = M.C. (% wb) of sample at time ti, Mi+1= M.C. (% wb) of sample at time ti+1

Determination of drier thermal efficiency

Thermal efficiency of the solar tunnel drier was estimated using the “Eq.(2).”

where, ŋth = drier thermal efficiency; m= the mass of water evaporated in time t = (mi – mf) kg, hfg = the latent heat of vaporization of water (kJ/kg), A= the area of solar tunnel drier in m2, I= the solar intensity in W/m2.

Sensory Evolution

Sensory evolution of organoleptic properties of dried products for colour and aroma was carried out by panel of nine judges of different age group and sex on the basis of ‘9’ point Hedonic scale defined as follows:

Like extremely -9, Like very much – 8, Like moderately – 7, Like slightly – 6, Neither like nor dislike – 5, Dislike slightly – 4, Dislike moderately – 3, Dislike very much – 2,Dislike extremely – 1

Performance Analysis

Time of drying and product quality at the end of drying are the most important factors deciding the performance of the dryer. Elaborate testing of the solar tunnel dryer was carried out under no load and full load conditions during the test.

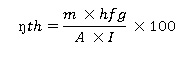

Performance evaluation of STD at no load conditions during the month of June

At no load conditions during summer season the temperature inside STD varies from 42⁰C to 61 ⁰C and was higher than the outside temperature by 12 ⁰C to 22 ⁰C and insolation varies from 440 to 820 W/m2.

Table 1: Variation of temperature and insolation during different seasons at no load conditions.

| Month | Ambient temperature ⁰C | Temperature inside STD ⁰C | Insolation, W/m2 |

| June | (30-44) | (42-62) | (440-820) |

The fig.1 shows average variation of insolation (W/m2), ambient temperature (⁰C) and average temperature inside solar tunnel dryer (⁰C) on different days at different time intervals in the summer month (June). During this period solar tunnel dryer was at no load conditions.

|

Figure 1a: Average temperature and insolation variation with time during June. Click here to View figure |

Load test of solar tunnel dryer for garlic drying

Garlic is a traditional crop used as spices in India. It has a lot of health benefits and generally available as a fresh product in the local market, but nowadays demand of garlic in powder form is increasing day by day.9 During drying of garlic the variation of ambient temperature, temperature inside the dryer and solar radiation intensity with respect to time is shown in Figure 4.2. The maximum temperature inside the solar tunnel dryer in upper and lower tray was recorded to be 64 ºC and 40 ºC during the period of drying. The average temperature inside the dryer was 55 ºC while the average ambient temperature was 36 ºC. Temperature attained inside the drier was good for drying. A similar study presents that for drying of green olives temperature between 50–70 ºC obtained inside the dryer was good enough for drying.8

|

Figure 2a: Average temperature and insolation variation with time during drying of garlic Click here to View figure |

Drying time required for garlic under STD

For experiment with load, 245 kg of garlic having initial moisture content 63% to 70% (w.b) was divided into four parts and then after giving treatments the samples were loaded in solar tunnel dryer during the month of June 2011.The experimental data were recorded after every two hour from 10 a.m. to 4 p.m. on each drying day. It was observed that initial weight of T1 garlic (frozen garlic) was reduced from 20 kg to 6 kg 500g with initial moisture content 66% (w.b) to finally moisture content of 9% (w.b) similarly initial weight of T2 garlic (Frozen + Pressed ) was reduced from 166 kg to 57 kg and T3 garlic (without any treatment) was reduced from 13 kg to 4 kg 500g and weight of T4 garlic (without any treatment but pressed) was reduced from 46 kg to 16 kg and initial moisture content varies from 63% to72% and finally moisture content observed was 9% to 10% (w.b). The drying period was observed as 8 to 10 days to reduce moisture content of garlic.

The fig.3 shows variation of moisture content reduction % (w.b) on different days during the month of June. During this period solar tunnel dryer was loaded with garlic. The drying was carried out from 63%-72% (w.b) to 9% -10% (w.b) and was completed in eight to ten days.

|

Figure 3: Moisture content (w.b) variation on different days during drying of garlic. Click here to View figure |

Fig. 4 shows moisture content reduction per day and drying rate variation per day. It was observed that drying rate was higher during the starting days of drying as compared to the end days. Following regression equations were developed and shows the relationship between drying rate and moisture content of the product during drying.

For T1

y = 0.000x2 + 0.008x – 0.012 R² = 0.965

For T2

y = -0.000x2 + 0.017x – 0.005 R² = 0.981

For T3

y = -0.000x2 + 0.029x – 0.224 R² = 0.928

For T4

y = -0.000x2 + 0.046x – 0.347 R² = 0.978

It was observed from the equations that drying rates were observed higher for T2.

|

Figure 4: Drying rate variation with moisture content of garlic. Click here to View figure |

Thermal efficiency of solar tunnel dryer

The overall thermal efficiency of STD was calculated by using the formula as given in section 3.3. During the first day of drying the dryer had higher efficiency and it reduced during the following days. This was mainly because at the initial stage of drying, products had higher moisture content and a higher amount of water was evaporated. During drying of garlic average thermal efficiency was 13.45%.

Organoleptic Evaluation

Sensory quality was evaluated for different parameters, i.e. color, appearance, flavor, odor, taste and overall acceptability. The score ranged from 1 to 9 which represented “Like extremely” to “Dislike extremely” The dried samples were tested by 50 judges. The mean sensory score of dried garlic powder has been shown in Fig 5.

|

Figure 5: Mean score of organoleptic evaluation of dried garlic powder. Click here to View figure |

Conclusion

The temperature inside the dryer ranges from 26 to 64 ºC during the drying period, which was sufficient for drying of garlic in 9 days. This range is considered as the best temperature for drying of agricultural produce ass temperature above 65 ºC is not appropriate for drying.11 The final dried garlic powder was free from impurities like dust, etc. and was found to be good in terms of color and aroma. The dryer can be easily constructed and used for large scale drying as the results are satisfactory.

Acknowledgements

The author appreciates the help and support received in the form of guidance and money from the faculty and staff of college of Agricultural engineering and technology, CCSHAU, Hisar, India.

References

- Esper A, Mu¨hlbauer W. Solar tunnel dryer for fruits. Plant Res Develop. 1996;44:61–80.

- Zaman MA, Bala BK. Thin layer solar drying of rough rice. Solar Energy. 1989;42(2):167–71.

CrossRef - Tiris, C., Tiris, M., & Dinc,er, I. (1996). Energy efficiency of a solar drying system. International Journal of Energy Research. 20(9),767–770.

CrossRef - Lahsasni, S., Kouhila, M., Mahrouz, M., Idlimam, A., & Jamali, A. Thin layer convective solar drying and mathematical modelling of prickly pear peel (Opuntia ficus indica). Energy. 2004;29(2):211–224.

CrossRef - Sharma, Atul, C. R. Chen, and Nguyen Vu Lan. “Solar-energy drying systems: A review.” Renewable and sustainable energy reviews. 2009;13(6):1185-1210.

CrossRef - Kamil Sacilik *, Rahmi Keskin, Ahmet Konuralp Elicin (2006). Mathematical modelling of solar tunnel drying of thin layer organic tomato. Journal of Food Engineering. 2006;73:231–238.

CrossRef - Bala, B. K. and Janjai,S.Solar Drying Technology: Potentials and Developments. Energy, Environment and Sustainable Development. 2012;69-98.

CrossRef - Colak N, Hepbasli A. Performance analysis of drying of green olive in a tray dryer. J Food Eng. 2007;80:1188–93.

CrossRef - Condorı, M., Echazu, R. and Saravia, L. Solar drying of sweet pepper and garlic using the tunnel greenhouse drier. Renewable Energy. 2001;(22):447–460

CrossRef - Rapusas, S. and Driscoll, H. The thin-layer drying characteristics of white onion slices. Drying Technology. 1995;13(8&9): 1905–31.

CrossRef - Rathore NS, Panwar NL. Design and development of energy efficient solar tunnel dryer for industrial drying. Clean Tech Environ Policy. 2010. doi:10.1007/s10098-010-0279-3.

CrossRef